How To Build a DIY Murphy Bed and Bookcase

A cozy extra bed when you need it, a handsome showpiece when you don't. We'll show you how build a Murphy bed.

Multiple Days

Advanced

More than $1000

Introduction

Combine a Murphy bed with a bookcase to create the ultimate comfort and storage space for the bedroom. Here's how to build a Murphy bed.Tools Required

- Brad nailer (or micro pinner)

- Drill

- Jigsaw

- Miter saw

- Pattern bit

- Router

- Table saw

Materials Required

- 2 - 4’ x 8’ x 1/4” oak plywood

- 4’ x 8’ x 1/2” MDF

- 5 - 4’ x 8’ x 3/4” oak plywood

- 60 bd. ft. - 3/4” solid oak*

How to Build a Murphy Bed

When William Lawrence Murphy filed patents for his space-saving bed around 1900, he couldn’t have known he was solving a 21st-century problem: the need for a home office or hobby space, plus extra sleeping space for guests. Although his invention has been improved over the last century, the basic idea is still brilliant.

Building a Murphy bed requires some precision — you must install the hardware exactly according to the instructions. But the woodworking here is actually simpler than that required for many bookcases. There are no dadoes, mortises or tricky joinery.

And all of the door frames are impostors. They look exactly like classic rail-and-stile frames, but they’re just 1/4-in.-thick solid wood applied to plywood. The bookcases flanking the bed are optional.

Check out this other disappearing bed and bookshelf project by a Family Handyman reader.

DIY Murphy Bed: Designed to Pamper Your Guests

A Murphy bed can be incredibly simple. Some are just an upright box containing a fold-down bed. But this is a deluxe version. Aside from the handsome design and storage spaces, we included some convenience features to make guests comfortable.

We added pullout tables on both sides mounted on drawer slides. Inside the side cabinets, display lights act as nightlights. And on the headboard, we mounted a touch knob so guests could switch on lights above the bed. No groping for a light switch in a dark, unfamiliar room.

Pullout tabletops function like nightstands — the perfect spot to set a book or a cup of bedtime tea.

Lights and switches built into the side cabinets aren’t just decorative. They’re functional, too.

Just touch a knob on the headboard to operate the dimmable reading lights above the bed.

Murphy Bed Hardware

Hardware kits include folding legs that support the foot of the bed, pivots that let the bed swing down and — most importantly — gas pistons that operate like the pistons on a hatchback. The latter lifts most of the weight of the bed when you close it.

There are lots of online sources for Murphy bed hardware. We ordered ours ($375) from rockler.com and were impressed with the quality of the hardware and the detailed instructions. Twin-, full- and queen-size kits are available.

Aside from the hardware, we spent about $115 on lighting kits specifically for Murphy beds and bookcases.

Before You Build a Murphy Bed

Don’t begin this project until you have the Murphy bed hardware on hand; you may need to alter our design slightly to suit different hardware.

Also be sure the room and furniture will accommodate the bed. Our bed protrudes 80 inches from the wall. Most of the materials you’ll need are available at home centers. The exceptions are the Murphy bed hardware and 1/4-in.-thick solid oak.

You can order 1/4-in. hardwood online (walllumber.com is one source) or “resaw” thicker boards.

Note: Single, double and triple letters in the instructions that follow indicate corresponding figures, diagrams and materials. Click the bold link at the end of the story to reference them all in one convenient place.

Project step-by-step (11)

Build the Inner Frame

This project requires a large assembly table. A full sheet of 3/4-in. plywood screwed to a pair of sturdy sawhorses does the trick. Otherwise, you’ll need to work on the floor.

Assemble the struts (GGG) from stock that’s at least 1/4-in. too long and trim them to final length after assembly. Then join them to the frame sides (HHH) with screws. Next, try building one of these amazing platform beds.

Assemble the Side Rail

The rest of the bed frame is made from oak plywood (G through J). The bed rails get 1-1/2-in. edging (KK) on the end and 3/4-in. edging on the top (LL). The side rails are plywood strips edged with solid wood.

Clamp the top edging in place, using cauls to distribute the pressure. You’ll need a long clamp to attach the end block edging. To extend the reach of a pipe clamp, add another length of pipe using a coupler.

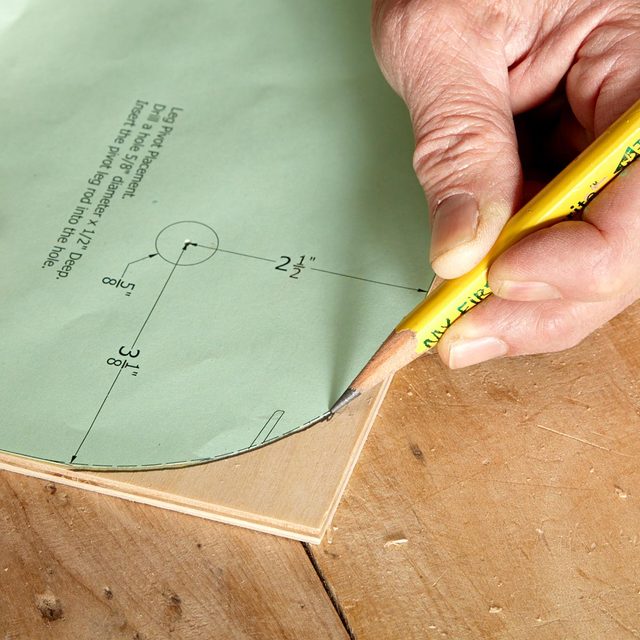

Make a Template for the Side Rails

Trace along the paper template and then cut a template from 1/4-in. plywood. The plywood template serves double duty as a drilling guide and a routing pattern. Use the template to position hardware holes and to mark the curves.

Rough cut the curves with a jigsaw. Smooth the curves by sanding or by running a pattern router bit along the template.

Drill the Hardware Holes

The template positions the holes perfectly. A stop block ensures the correct depth. Rough cut the curve, then finish it with a router and a pattern bit guided by the template.

Assemble the Bed Frame

Attach the head rail, foot rail and side rails to the inner bed frame. Cut two pieces of plywood for the bed face panels (A). Trim one side and the top edge (where the foot of the bed will be) of each panel with 1/4-in. edging.

Lay the two panels face down on your bench and butt the two pieces together so the hardwood edges are to the outside. Lay the assembled bed frame on top of the panels and attach with screws. Flip the entire bed frame over so you can cover the face panels with false doors and drawers.

Add False Doors and Drawers

With a helper, carefully turn over the bed frame assembly so it’s face up on your bench. Rip the stock for the faux panels and drawers (UU through BBB) to width. Use 1/8-in. spacers to create gaps between the faux doors and drawers and attach with glue and brads or pins. Use the glue sparingly to avoid squeeze-out, which is tough to clean up.

Go ahead and mount the pulls and knobs. Be careful to avoid the inner frame structure when placing your hardware. Remove all the hardware until after the cabinet is finished. Cut and fit the mattress supports (X). Don’t screw these into place until final assembly.

If you find this project a little too ambitious for your skill level, that’s OK. Check out these six woodworking projects you can make with just a jigsaw.

Build the Shelf Units

Cut the bed cabinet plywood parts (B, C, E). Glue and clamp 3/4-in. hardwood edging (MM) on the bed cabinet verticals. Add 1/4-in. edging to the top and bottom edge of the headboard. Lay out and drill for the hardware.

If you plan to add the light fixtures, now is the time to cut the 2-7/8-in.-dia. holes in the bed header panel. Follow the instructions in the kit. Screw and glue the mounting cleats (JJJ) to the ends of the header board. Add the header front and back (BB) according to the instructions. Wait to assemble the bed cabinet.

The bookcases on either side of the bed cabinet are assembled with the same screw and cleat system used for the bed cabinet. Cut the plywood parts (F, N through R, U) and cleat stock (KKK through NNN). Cut 1/4-in.-deep by 3/8-in.- wide rabbets along the back edge of the middle and bottom shelves and on the cabinet sides between the two shelves. Assemble the side cabinets with screws.

Cut the face frame and pullout parts for the side cabinet (DD through HH). Build the face frames with pocket screws or dowels. Clamp and glue the face frames to the cabinets. Cut and glue the hardwood edge on the middle shelf. Build and mount the pullout.

Add the faux panel frames (CCC through EEE) to the doors. Mount the doors. If you’re using Euro-style cup hinges, be sure to order the ones made for thick doors. Cut and fit the backs (Y).

Build the Fascia Boxes

Cut the parts for the three cabinet top and fascia assemblies (D, K through M, S, T, V, W, PP through TT). Assemble the fascia boxes with screws and glue. Cut and fit the 1/4-in. oak fascia with mitered corners. Trim the 1/2-in. plywood in the same manner.

Attach the fascia trim board to the bottom of the fascia boxes, then screw the box down onto the top of each cabinet. If you’re using lights, take a jigsaw and make a 4-in.-dia. hole in the bottom of each fascia trim board. Cut the top parts (D, M, CC). Cut a 15-degree bevel on the top trim on the table saw.

Cut and miter the top trim to fit. Wait to attach the tops until installation. Drill ventilation holes in the cabinet tops for the lights.

Assemble the Bed Cabinet

You’ll need at least one helper for this phase of the project.

The Murphy bed can be disassembled as far as you need to get the bed into the room. The only thing remaining that’s large and cumbersome is the bed frame.

If you need to maneuver the bed through a narrow staircase or other obstacle, consider leaving off the middle drawer and the two horizontal dividers on the faux front. These bridge the two face panels; once installed, they cannot be easily dismantled for moving. You can reassemble the bed frame in the room and add the drawer and horizontal dividers at that point.

Before installation, reattach all the bed hardware but leave the bed stops, pulls and handles off for now. Place a pad on the floor about two feet in front of the wall where the bed will be mounted. Lay the bed frame face down on the pad with the head of the bed frame toward the wall.

Mount the bed cabinet sides to the bed frame on the metal pivots. At this point, the cabinet verticals should also be face down alongside the bed frame. Attach the headboard with screws.

Screw the Cabinet to the Wall

With a helper on the other side, lift the bed cabinet to the vertical position. Be sure the leg support is folded up before you lift the cabinet. Then attach the bed header assembly to the top.

Next, lift the bed frame into the vertical position while your helper holds the cabinet. Be careful. Until the cabinet is attached to the wall, you need someone to hold the bed in place and keep the cabinet steady.

With the bed cabinet and frame vertical, attach the gas springs. Snap the ends of the springs onto the ball stud plates on the bed frame and the cabinet verticals. The springs are marked with a “This End Up” sign; follow the directions carefully. Attach the bed stops from inside the cabinet.

With the bed held in place by the gas springs, move the cabinet up against the wall. Mark the stud locations just above the bed header and attach with screws.

Add the Side Cabinets

Slide the bookcases in position and attach to the bed cabinet. All that’s left is to remount the crowns and add the tops.

Go ahead and pull the bed frame down and swing the leg supports to the floor. Without the mattress, the bed will want to close back up. Add a little weight to it to hold it down while you attach the two 1/4-in. plywood mattress supports to the inner frame. Add the elastic retaining straps and you’re ready to set the mattress into place.

Here are the cutting lists and additional figures and diagrams.