A Full Guide to Metal Roof Installation

Learn how to get roofing layers right with these metal roofing tips.

Multiple Days

Advanced

More Than $5000

Introduction

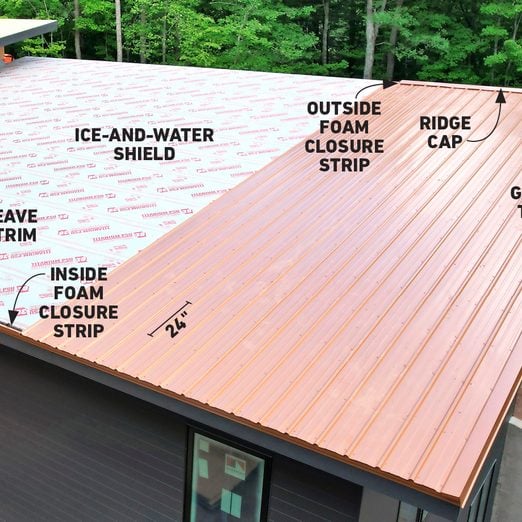

With its sleek, modern look, metal panel roofing was our first choice for the Getaway. It has no visible seams and is maintenance free — even a light rain will wash leaves and sticks off the roof. Even better, it won’t grow moss and algae in the shade of the Wisconsin woods.A metal roof will reduce cooling costs by reflecting heat and last 50 to 70 years. Armed with a basic understanding of the anatomy of a metal roof, along with a few tips, you can install one yourself in just a few days.

Pro tip: It’s all about the layers. When it rains, a roof sheds water from one layer to the next until it runs off the roof. Build roof layers the right way and your home will stay dry inside for its entire life.

Tools Required

- Basic carpentry tools

- Aviation snips

- Hand Seamer

- Fall Protection

- Metal Shears

- Drill/Driver

Materials Required

- Metal Roofing Panels

- Ice and Water Shield

- Roofing Nails

- Eave Trim

- Gable Trim

- Ridge Cap

- Sidewall Flashing

- Self Tapping Roofing Screws

- Metal Roofing Sealant

- Inside Foam Closure Strips

- Outside Foam Closure Strips

- Butyl Tape

- Roofing Vent Boots

Project step-by-step (11)

Apply the underlayment

-

The first layer on top of the plywood or OSB roof deck is underlayment. For this, we chose a self-healing ice-and-water membrane to protect the shallow-pitched roof deck.

-

The tricky part in laying the underlayment is keeping it flat and wrinkle-free. Unroll the underlayment across the roof while removing the bottom half of the adhesive backing. Overlap the previous layer by six to eight inches. Once the underlayment is rolled out, cut it flush and pull the rest of the adhesive backing out from underneath.

Order panels to fit

- If possible, avoid seams in your roof. They don’t look great, and it could lead to water getting underneath the panels.

- I had our metal roofing panels cut to fit the length of our roof. They were nearly 32 feet long and had to be delivered on a flatbed trailer. Of course, you’ll need a large lift to hoist the panels on top of the roof. If you don’t have one, you’ll have to order more manageable lengths.

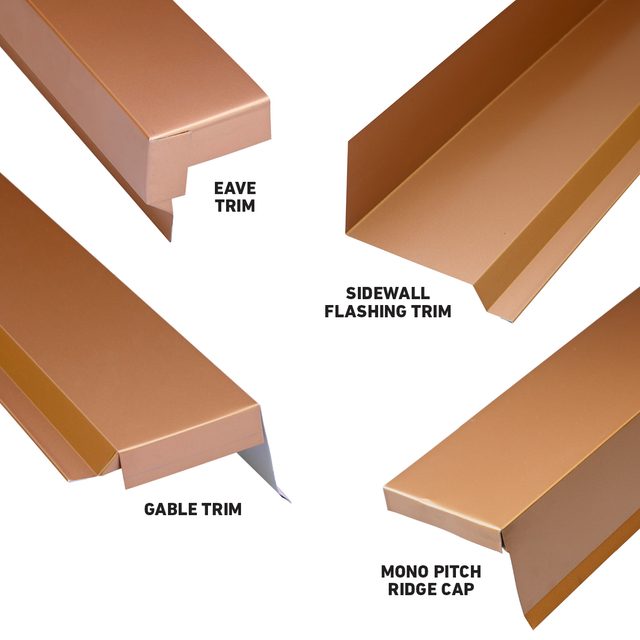

Bend trim ends closed

- Before you install the trim, cut and bend the leading end to wrap it around the corner. Make a series of one-inch cuts with aviation snips at each bend to create tabs. Fold the tabs in with a hand seamer to meet a wall or a corner, or to close a gap created by the trim. Each trim is a different shape, requiring unique cuts and bends.

- Install the eave trim tight to the fascia and fasten it to the roof deck over the underlayment with one-inch roofing nails. In warmer climates, the eave is attached before the underlayment. In northern Wisconsin, where ice dams are common, we install these atop the underlayment to protect the entire roof from dams.

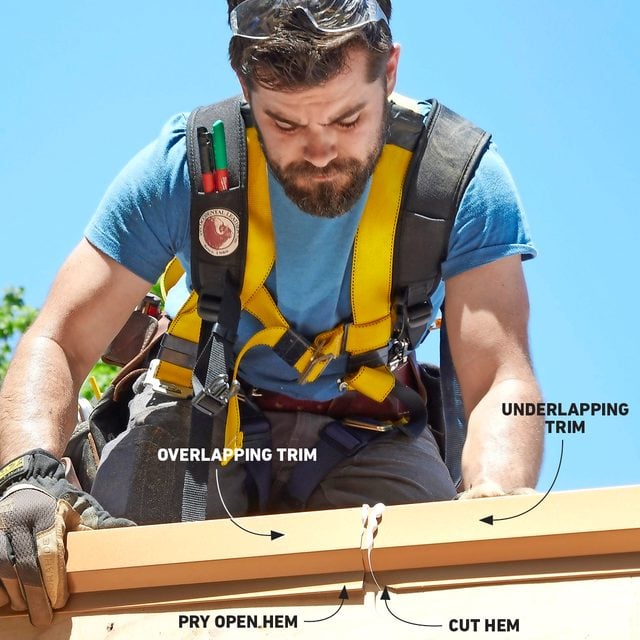

Splice and overlap trims

- Where two trim ends meet, you’ll splice them together. First, cut the bottom hem of the underlapping trim at an angle. After installing the underlapping trim, apply sealant on top. Pry open the bottom hem of the overlapping trim and slide it over the angle-cut hem of the underlapping trim.

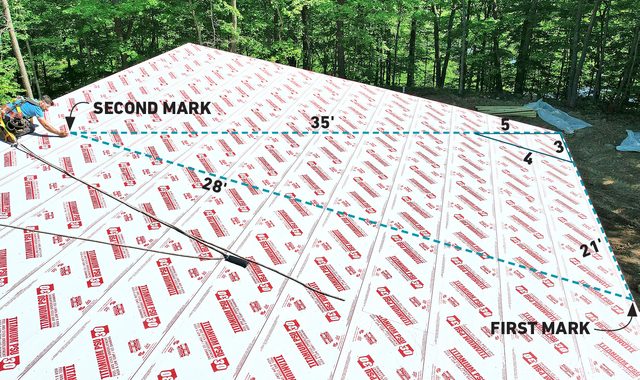

Snap a square reference line

- A square reference line is important for installing roofing panels evenly. Use the 3-4-5 method to establish a reference line 90 degrees to the eave.

- First, make a mark along the eave three feet (or any multiple of three) from the corner. At that mark, measure four feet (or the same multiple of four) toward the ridge. Then, from the original corner, measure five feet (or the same multiple of five) and mark where it intersects the second mark.

- Snap a line from the first three-foot mark through the intersection of the second and third marks. Since the Getaway roof is larger, I measured to 21 feet, 28 feet and 35 feet (seven times three, four and five) to make my square reference line.

Set the panels

- Place each metal panel on an inside foam closure strip. These strips are shaped to fit the corrugated underside of the panel and keep bugs and water from getting underneath.

- Position the closure strips along the eave about one inch from the edge and stick them to the panels with butyl tape. Run a bead of sealant on top of the closure strip, then set your panel so it overhangs beyond the eave by one inch. Adjust the panel so any measurement from it to the reference line is the same at the top and bottom.

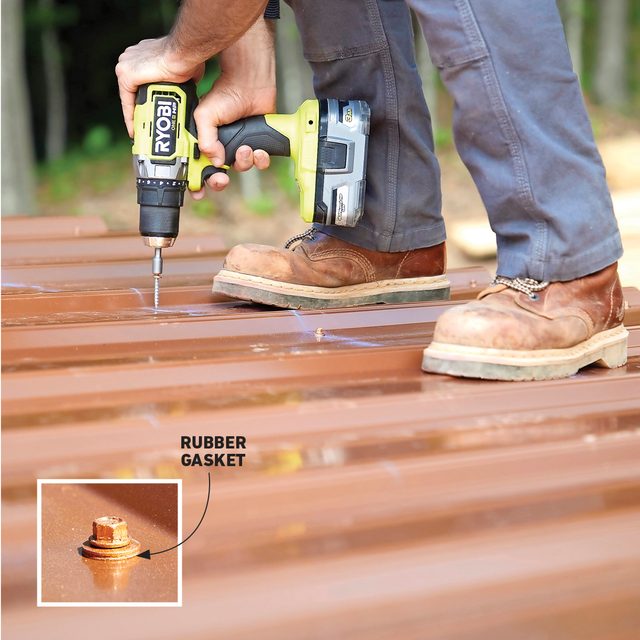

Drive screws just right

- Fastening the panels just right is the key to a watertight roof. Here is what you should know:

- At the eave, place screws on both sides of every rib and lined up to go through the foam closure strip.

- Each row should be spaced no more than 24 inches with one screw at each rib on the overlapping side.

- Start at the bottom, fastening across the panel in rows, working toward the ridge.

- Drive screws to seat flat on the roof; a crooked screw won’t seal.

- Don’t over-tighten or under-tighten. Tighten just enough to compress the rubber gasket to the edge of the screw head, not past it.

- Clean up any metal shavings or burrs right away. They will rust.

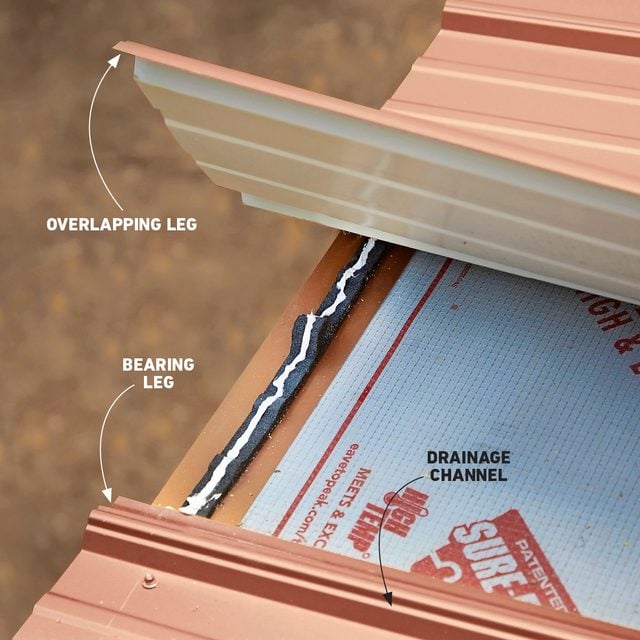

Overlap the panels

- The two edges of the metal panels are different. The edge that overlaps has a shorter rib leg that doesn’t contact the roof surface when laid flat. The rib on the underlapped side has a drainage or anti-siphon channel to keep water moving toward the eave. Overlap the last rib on each panel; they should nest together perfectly.

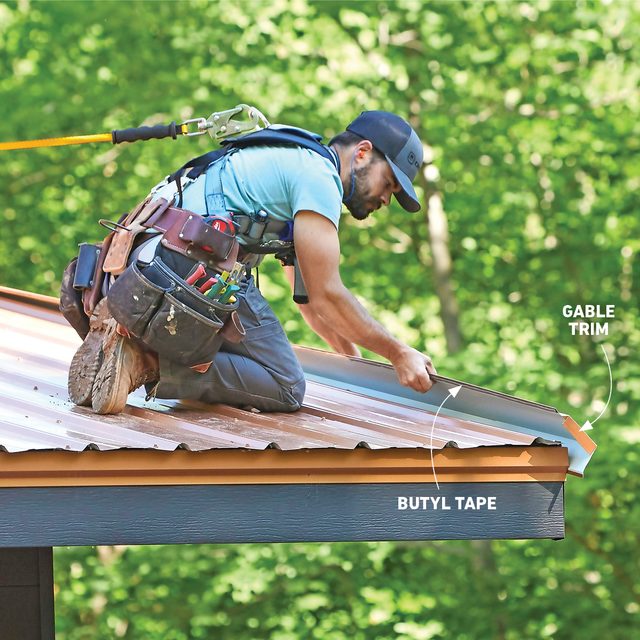

Cover the rake edge

- After all the panels are fastened, it’s time to attach the gable trim. This cleans up the edge of the panel and keeps rain and snow from getting under the roof panels and siding.

- After you bend the end of the trim to meet the corner at the eave, apply butyl tape on the underside of the trim where it lands on the flat part of the roof panels. Press it in place and drive screws every 12 inches right over the butyl tape.

Secure the ridge cap

- To cap the roof, adhere a line of outside closure strips with butyl tape four inches from the top of the peak; this is where you’ll fasten the ridge cap to the roof with screws. Apply a bead of sealant on the foam closure, then fit the ridge cap on the peak and fasten with two-inch screws to the roof deck through every rib.

- With the cap of the roof complete, all the water that lands on the roof will exit the roof without ever touching the underlayment. Check out our guide to DIY roof installation.