What is Treated Wood?

Like its name suggests, pressure-treated wood is wood that has been treated with chemicals while under pressure. Most treated wood is pressure-treated, but wood can also be surface coated. Surface coated means that the application of the preservative chemical is introduced by dipping, brushing or spraying the wood without being exposed to pressure. This is common when it’s necessary to treat the lumber or building components after they are installed.

Types of Treated Wood

There are two types of treated wood: preservative-treated wood and pressure-preservative-treated wood (pressure treated lumber). Wood treatment chemicals delay deterioration caused by fungi (rot) and make wood less appealing to potentially destructive insects. One common misconception is that treated wood is more resistant to water, but that’s not true. Treated wood will soak up just as much water as non-treated wood.

What is Treated Wood Used for

Treated wood is used for areas where the lumber will be susceptible to moisture, like uncovered areas outdoors. It is not for internal use. Moisture can cause serious issues to untreated wood, like warping.

How is Pressure-Treated Wood Created?

First, untreated lumber is placed into a large horizontal treating cylinder. The door is sealed and a vacuum is applied to remove most of the air from both the cylinder and the cells of the wood in the process. A preservative solution is then pumped into the cylinder and the created pressure forces the preservative solution into the empty wood cells, and then you have pressure treated lumber.

Why Does Pressure Treated Lumber Warp?

Most dimensional lumber is dried in a kiln, but treated wood is not dried after treatment. There are exceptions to this, such as foundation grade lumber and plywood, which needs to be dried to a moisture content of no more than 19 percent for lumber and 15 percent for plywood. This is referred to as Kiln Dried After Treatment (KDAT). Wood does most of its warping, twisting, and cupping as it dries. It’s hard to determine if you’re getting a straight board when it’s still wet.

Can I Make Wood Treatment Chemicals?

There’s a very easy, straight answer to that question… no! The American Lumber Standards Committee (ALSC) Treated Wood Program, operating under the Board of Review, currently has accredited independent third-party agencies in the United States and Canada that regulate this industry. Monitoring of treating plant production takes place under standards written and maintained by the American Wood Protection Association (AWPA) and ALSC policies.

In addition to that, all treated wood chemicals are regulated by the United States Environmental Protection Agency (EPA) as pesticides, and all pesticides sold or distributed in the United States must be registered by the EPA. With all of that regulation it is unlikely your local building official will accept “home-made” treated lumber.

Who Makes the Treated Lumber Rules?

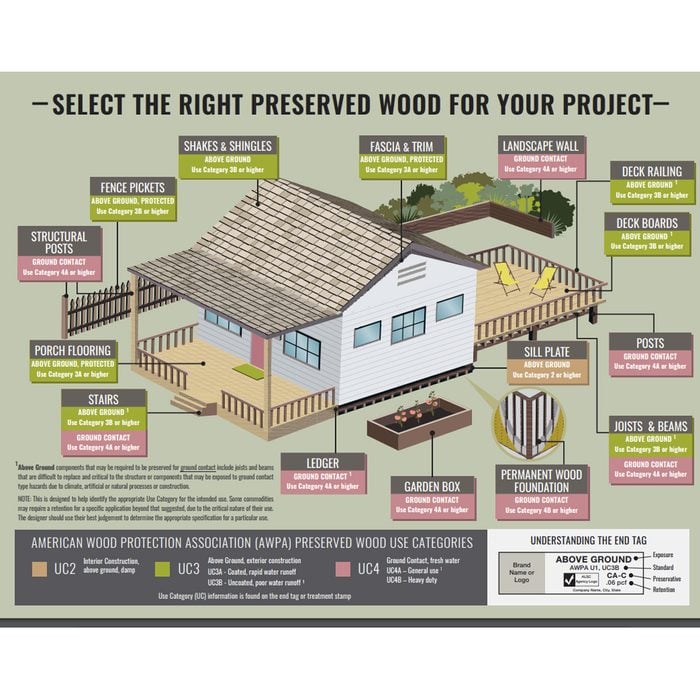

The American Wood Protection Association (AWPA) is responsible for spreading voluntary wood preservation standards. AWPA standards are referenced in both the International Residential Code (IRC) and the International Building Code (IBC). The Use Category System (UCS) designates what preservative systems and retentions have been determined to be effective in protecting wood products under specified exposure conditions. All wood products can be placed into one of five major Use Categories that clearly describe the exposure conditions that specified wood products can be subjected to in service.

These are further broken down into sub-categories to define the associated degree of biodegradation hazard and product service life expectations. Below is a brief chart showing some of the usage sub-categories and their intended use:

Which Treated Wood Should I Use?

The advantage of this new “Use Category System” is that it virtually eliminates the need to try and remember which chemical treatments are intended for each specific use. Now, with a few saltwater exceptions, all you have to know is whether the pressure treated lumber is intended for above ground or ground contact.

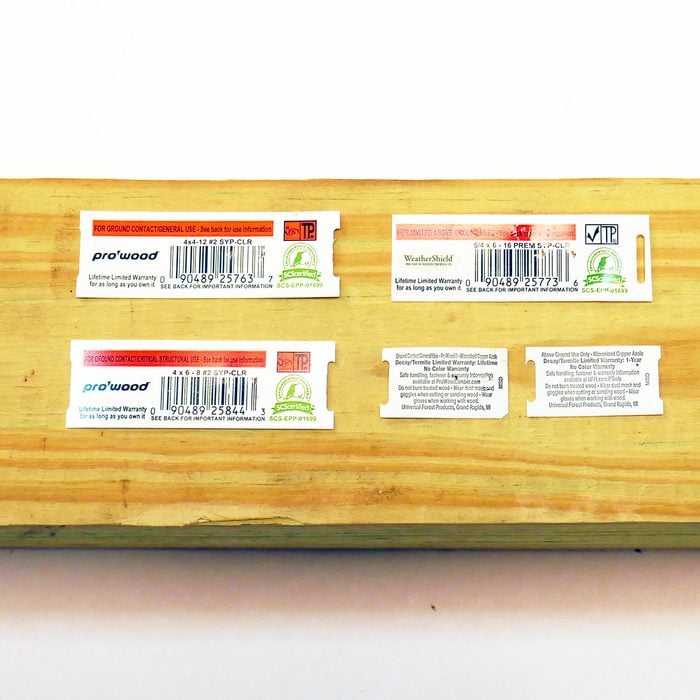

How Can I Differentiate Treated Lumber?

Most pressure treated lumber will have an end tag to identify what type of chemicals it was treated with and whether it is rated for “ground contact” or “above ground use” only.

Is Arsenic in Pressure Treated Lumber?

There is still some arsenic in some pressure treated lumber, but not as much as there used to be. For many decades one of the most common preservatives used in the residential construction industry has been Chromated Copper Arsenate (CCA). And YES, Arsenate is a type of arsenic and is considered poisonous when exposed to high enough amounts.

In the early 2000’s, public concerns arose about arsenic-contamination in public children’s playgrounds, which led to larger concerns about the overall safety of CCA treated wood. In 2003, the EPA arranged a voluntary agreement with manufacturers of wood treatment chemicals to remove lumber treated with CCA from most residential construction uses. CCA treated wood may still be used for permanent wood foundations, highway construction, fence posts, poles used as structural members on farms, marine construction, and lumber and timber for salt water use.

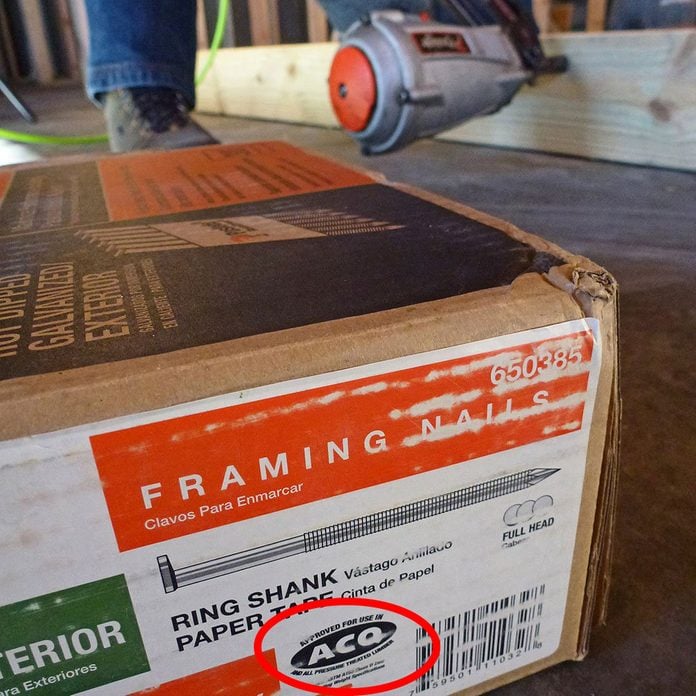

Do I Need Special Fasteners for Treated Wood?

Yes, fasteners such as nails, screws, and bolts used on treated wood needs to be hot-dipped zinc-coated galvanized steel, stainless steel, silicon bronze or copper. Check the label on the fasteners to see if they will work with your treated wood.

(Note: the IRC contains an exception for ½-inch diameter (or larger) steel anchor bolts.

Does Treated Wood Corrode Aluminum?

Yes. Most of the new chemical treatments contain copper and should never come in direct contact with aluminum. Total failure caused by corrosion can occur in less than a year. Many contractors isolate aluminum flashing and trim from pressure treated lumber with building tape or house wrap.