How to Install Ceiling Fans

It's easier than you think, even on an angled ceiling.

A full day

Intermediate

$101–250

Introduction

A ceiling fan improves cooling in summer and heating in winter. The result: You feel more comfortable while you save on utility bills. And installing them yourself is much easier, thanks to new, strong hanging systems and electronic controls. We show you how to avoid common pitfalls when installing one yourself.Tools Required

- 4-in-1 screwdriver

- Hammer

- Level 2-ft.

- Needle-nose pliers

- Non-contact voltage tester

- Nut driver

- Tape measure

- Wire stripper/cutter

- Wrench set

Materials Required

- Ceiling fan

- Fan brace and box assembly

- Switch

- Wire connectors

Project step-by-step (13)

Overview and getting started

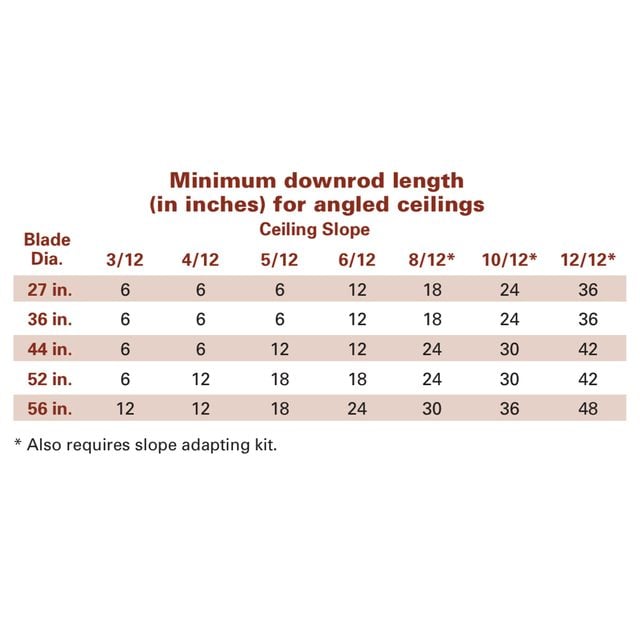

Measure the ceiling slope

Determine the ceiling slope by holding a 2-ft. level against the ceiling and measuring the vertical distance from the level to the ceiling. Divide that number by 2 to get the drop over 12 in. of horizontal run, 3/12 slope in our case. See the chart below to determine the minimum downrod length for the blade diameter you’d like.

You don’t have to be a “Casablanca” aficionado to appreciate the elegance a ceiling fan can bring to your home. And you can enjoy a fan all year long as it creates a welcome breeze in the summer and circulates warm air in the winter.

Installing a ceiling fan (technically called “paddle fans”) used to be frustrating, to say the least. Most of the time you had to wing it because specialty hanging systems were poorly developed or nonexistent. Nowadays, most manufacturers have designed versatile fan mounting systems that take the hassle out of installing a ceiling fan. When you add in the improved, stronger ceiling boxes, you’ll find that just about any ceiling fan can go up quick and easy on any ceiling, sloped or flat.

In this article, we’ll illustrate crystal-clear instructions that go beyond the basic set included with the fan. We’ll also show you how to avoid common pitfalls like putting on parts in the wrong order and forgetting to slip shrouds on ahead of time. Some mistakes are more serious than these. Standard electrical boxes or blades hung too low can be downright dangerous.

In addition to the fan, you can buy accessories like electronic controls, fancy light packages and furniture-grade paddles.

Put up a new fan in a leisurely Saturday afternoon

If everything goes well, you can put up a ceiling fan in a couple of hours, including cleanup. In most cases, the whole job will take only a hammer, a screwdriver, a 3/8-in. nut driver and a wire stripper.

Most of the time, the wires that fed a previous ceiling fan wiring light fixture are adequate for hooking up a new fan. If you have a ceiling fan wiring arrangement that’s different from ours and you are unfamiliar with wiring techniques, consult an electrician or building inspector for help.

Follow the photo series for basic installation steps that apply to more than 95 percent of all fans. There may be small variations, particularly when it comes to the light and blade mountings, so you’ll still need to consult the instructions provided with your fan. As with any other electrical work, you may need an electrical permit from your local building department before starting the job. The inspector will tell you when to call for an inspection.

Fan Height Requirements

Manufacturers generally require that fan blades be at least 7 ft. above the floor. Since most fan and motor assemblies are less than 12 in. high, they’ll fit under a standard 8-ft. ceiling with the proper clearance.

Angled ceilings require that you install “downrods” (also called extension tubes or downtubes) that will lower the motor and fan blades so they’ll clear a sloped ceiling surface. The more space between the ceiling and the fan, the better. The fan will have more air to draw from, and you’ll feel more air movement because the blades are closer to you.

Most fans come with a short downrod designed for mounting on 8-ft. ceilings. If your ceiling’s less than 8 ft., you’ll need to remove the rod provided and flush-mount the fan. But if you have a higher or sloped ceiling, purchase a longer downrod.

Knock out the old box and install a fan brace

Shut off the power at the main panel and remove the light fixture. Knock the existing electrical box free of the framing with a hammer and a block of wood, then pull the electrical cable free of the old box and through the ceiling hole. Leave the old ceiling fan junction box in the ceiling cavity unless you can easily remove it through the hole.

Tip: Before you blast out the box, bend back the plastic clamps or loosen the metal cable clamps so it’ll be easier to pull the electrical cable free after the box is loosened.

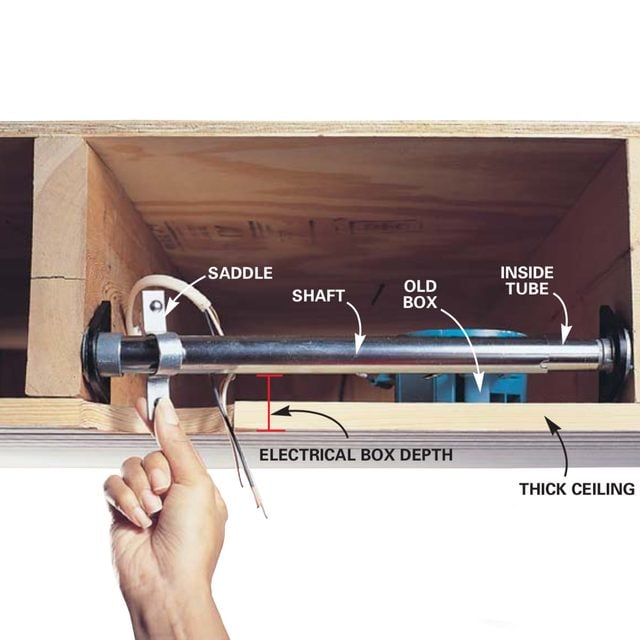

Install the ceiling brace

Feed the fan brace up into the hole, rest the flat edge of the feet against the ceiling and center the shaft over the hole. If your ceiling is more than 1/2 in. thick, as ours was, rotate the feet and position the rod the depth of the box from the ceiling. Rotate the shaft to secure the brace to the framing. Snap the metal saddle over the shaft so it’s centered over the hole.

Close-up of fan brace

The brace ends fit against the ceiling and the end screws drive into the joints as you rotate the shaft.

Before starting any work, shut off the circuit breaker that feeds the switch and light fixture. If there’s a working bulb in the fixture, turn it on. Then you’ll know you have the right breaker when the bulb goes out. Check the wires with a voltage tester to make sure they’re off after removing the fixture and when changing the wall switch.

The next step is to remove the existing plastic or metal electrical box and install a “fan brace” that’s designed to hold ceiling fans. Few conventional boxes are strong enough to support a ceiling fan, so don’t even think about trying to hang your fan from an existing box. Instead, buy a fan brace when you purchase your fan. You can choose braces that fasten with screws if the framing is accessible from the attic or if it’s new construction. Otherwise, pick a brace that’s designed to slip through the ceiling hole and through the electrical box. These braces (Photos 3 and closeup) adjust to fit between the framing members in your ceiling; you simply rotate the shaft to anchor them to the framing.

Most existing electrical boxes are fastened to the framing with nails, making them easy to pound out with a hammer and a block of wood (Photo 2). After you free the cable, just leave the old box in the cavity (Photo 3) rather than struggling to work the box through the ceiling hole. Then pull the cable through the hole and slip the fan brace through the opening and secure it, following the directions that came with the brace. Little feet on the ends of braces keep them the correct distance from the backside of 1/2-in. thick ceilings so the new electrical box will be flush with the surface. If you have a thicker ceiling (like ours), rotate the ends to achieve the correct spacing.

Install a new ceiling fan mounting box: electrical box and a ceiling fan wiring hanger bracket

Feed the existing wire through the cable clamp in the top of the new metal ceiling fan junction box, slip the box over the saddle screws, and tighten the nuts to clamp the box to the shaft with a nut driver or a deep-well socket. Crimp a loop of grounding wire three-quarters around the grounding screw and tighten the screw.

Attach the hanger bracket

Position the hanger bracket so that the opening in the bracket is on the uphill side of the sloped ceiling. Then screw it into the box with the special screws provided with the fan brace.

Pull the ceiling fan wiring into the new box, mount the box onto the brace (Photo 4) and attach the fan hanger bracket (Photo 5).

Assemble the fan and hang it

Insert the correct size downrod

Place the motor right side up, thread the wire through the downrod and insert the downrod into the mounting collar.

Fasten the downrod securely

Slip the downrod pin through the collar and tube, lock it into place with the cotter pin, and tighten the screws and locknuts.

Tip: Tighten the locknuts firmly. Loose nuts are the most common cause of wobbly fans.

Prepare the hanging ball

Slip the collar cover, then the canopy over the downrod. Slide the ball over the downrod and push the pin through both sets of holes, then lift the ball over the pin and tighten the set screw.

Hang the motor

Lift the assembly over the open side of the bracket and lower it into place. Rotate the motor until the ball slot locks into place over the tab on the bracket. Your fan will include assembly instructions. Photos 6 – 9 will help you with several key steps.

Wire the fan, fan light and switch

Connect ceiling fan wiring at the fan: Know your ceiling fan wire colors

This is what you need to know about ceiling fan wire colors: Connect the bare ground wire from the box to the green ground wire on the bracket with a wire connector. Connect the white neutral wire from the motor to the neutral wire from the box. Connect the blue and black wire from the motor to the black hot wire from the box and neatly fold them into the box.

Attach the fan blades

Screw the fan blades to their brackets and screw the brackets to the bottom of the motor. It’s easiest to hold the screw in the bracket with the screwdriver while you lift the blade assembly into position. Then drive the screw in.

Connect the light pod and radio receiver

Place the radio receiver into the switch housing/light pod assembly and connect the light pod wires according to the manufacturer’s instructions. Note the settings on the receiver’s code toggles so you can dial in the same settings on the electronic controls at the wall switch. Now loosen the screws in the switch-housing hub halfway. Plug the motor ceiling fan wiring into the receptacle on the receiver and twist the switch housing into place on the hub. Retighten the screws.

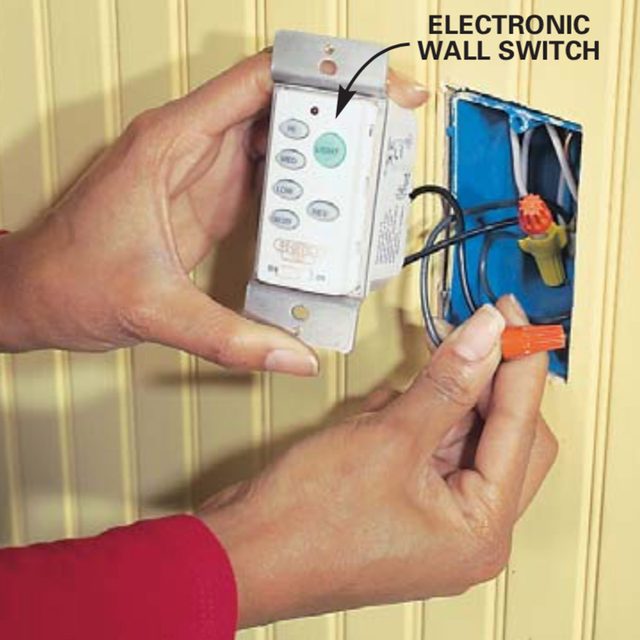

Connect the switch

Check and reset (if necessary) the code toggles on the wall-mounted electronic switch to match the ones on the receiver. Remove the existing wall switch and connect the two black wires on the new switch to the ones that were connected to the old switch with wire connectors. Screw the switch into the box and install the cover plate.

New electronic controls save you from running additional ceiling fan wiring.

Since most fan installations are retrofits into existing electrical boxes, there’s usually a single electrical cable connecting the fixture to a single wall switch. You can leave the switch and use it to turn the fan on and off, then use the pull chains on the fan to control fan speed and lights. A second option is to install electronic controls. Higher-quality fans give you the option of adding a radio receiver kit. The receiver accepts signals from a special wall switch (included in the kit) to control the fan and light separately without additional wiring. The receiver also accepts signals from a handheld remote, so you can operate multiple fans and fine-tune fan speed and light intensity from your La-Z-Boy. Electronic switches are matched to fans by flipping code toggles in the controls and the fan, just like with your garage door opener. Installing an electronic switch (Photo 12) is a snap. The receiver drops right into the fan housing and plugs into the bottom of the motor.

If the old light is fed by two three-way switches instead of a single switch, the control options are a little more complicated. You have three choices:

- Leave the existing switches in place and turn one of them on. Then use a remote control to control the fan and lights.

- Use the existing switches and control the fan and lights independently with pull chains.

- Disable one of the three-way switches and rewire the other one to receive a wall-mounted electronic control. Sorting out all the wires is complex. You’ll need an electrician’s help for this.

Buying a Ceiling Fan

If you haven’t walked under a large fan display yet, hold onto your hat. You’ll be overwhelmed by the selection of colors, styles and accessories, especially if you visit a ceiling fan store. If you intend to use your fan regularly, invest in a high quality model. You’ll get a quieter, more efficient, more durable unit. If you spend beyond that amount, you’re usually paying for light packages, radio-actuated remote and wall controls, style, and design (fancier motor castings, inlays, blade adornments or glasswork). If you spend less, you’re likely to get a less efficient, less durable, noisier unit with fewer color, blade and electronic choices.

Choose the blade diameter that best suits the room visually and make sure the unit will fit under the ceiling without jeopardizing beehive hairdos.

Bigger rooms call for wider fan blade diameters.

The bigger fan will not only look better but also move more air.

Most ceiling fans are designed for heated, enclosed spaces. If you’re putting a fan in a screen room, a gazebo or other damp area, the building code requires you to use a “damp-rated” fan. These fans have corrosion-resistant stainless steel or plastic parts that can stand up to high humidity and condensation. If you live in a coastal area with corrosive sea air, or if you’re putting a fan in a particularly wet environment like a greenhouse or an enclosed pool area, you should choose a “wet-rated” fan.