Expert Tips for How to Install Drywall

Updated: Dec. 21, 2022Follow these tricks for a faster, trouble-free installation

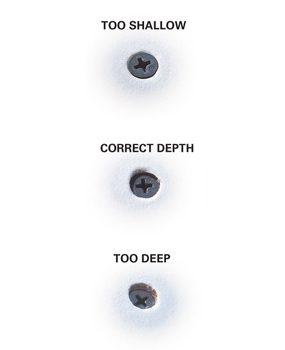

Adjust the screw gun tip for accurate depth

How to Put Screws in Drywall

Don’t be tempted to use your cordless screwdriver or regular drill to drive drywall screws. Neither will give you the precise depth control you need for trouble-free fastening. Use a screw gun instead. They’re reasonably priced and available at home centers and tool retailers.

Photo 1 shows how to adjust the screw gun to set screws at the correct depth. Practice driving screws on a scrap of drywall or in a closet to get the hang of it before tackling your room. Start by placing a screw on the magnetic driver tip. Then line up the screw with the center of the framing and squeeze the trigger to bring the driver up to speed. After the motor is running full speed, press straight in and don’t release the pressure until the clutch starts to ratchet. You’ll know by the clattering sound it makes.

Make sure the drywall is tight

Crooked studs or puffed-out insulation can prevent the drywall from lying tightly against the studs. If the gap is too large, the screwhead will pop through rather than pulling the drywall tight.

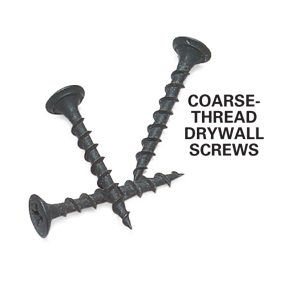

Tack with nails, but fasten with screws

How Many Screws Per Sheet of Drywall?

Buy 1-1/4-in. coarse-thread drywall screws to attach 3/8-in., 1/2-in. and 5/8-in. drywall to wood framing. Use fine-thread screws to attach drywall to steel studs. To answer the question “how many screws per sheet of drywall?” It all depends how big the piece of drywall is. But the most important part is to place screws 12 in. apart where the ends or edges of sheets butt at framing members, and along each framing member in the center of the sheet. Don’t use longer screws unless you’re screwing through soft material like foam insulation into the underlying framing. The screws should only penetrate the wood 5/8 to 3/4 in. Any deeper and they’ll be prone to popping later.

For a speedier job, take a tip from the pros and tack the perimeter of the sheets with several ring-shank drywall nails to hold it. Then return to drive the screws. This saves you the hassle of carrying the screw gun around while you’re supporting the heavy drywall.

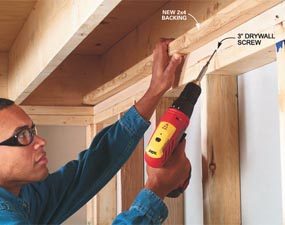

Provide solid backing on edges before hanging the sheet

Inspect inside corners where walls intersect and along the top of walls where they meet the ceiling. The goal is to provide at least 3/4 in. of exposed framing to drive screws into. If you can’t swing a hammer in tight spots, screw in blocking with 3-in. screws. Keep a few lumber scraps handy so you can add backing on the fly if necessary (Photo 2).

Mark the framing

It’s frustrating to have to guess where framing members are after they’re covered with drywall. Avoid this hassle by marking all the framing members before you start hanging the drywall. Mark the center of each ceiling framing member on the top plate of the walls (Photo 1). After you hang the ceiling drywall, mark the wall stud centers on the ceiling drywall and on the floor (Photo 2). Use a pencil when marking on drywall. Ink from markers and pens will bleed through the paint.

Remove the screws that missed the framing

Even with careful preparation, you’ll occasionally miss a stud, drive a screw too deep or have trouble driving a screw deep enough. The screws don’t usually back out easily. Photo 1 shows one method of removing screws with your screw gun. If this doesn’t work, slide a putty knife blade under the head and press it against the threads while you back out the screw with your screw gun, cordless drill or Phillips screwdriver. If you overdrive a screw and break through the paper, add another screw a few inches away and then remove the overdriven screw. Locate underdriven screws by sliding your taping knife over each line of screws and listening for clicks that indicate protruding screws. Use a screwdriver to twist them in a few turns, or remove them and drive a new screw alongside with the screw gun.

Required Tools for this Project

Have the necessary tools for this DIY project lined up before you start—you’ll save time and frustration.

- 4-in-1 screwdriver

- Chalk line

- Cordless drill

- Drywall saw

- Dust mask

- Hammer

- Level

- Screw gun

- Shop vacuum

- T-square

- Taping knife

- Utility knife

Required Materials for this Project

Avoid last-minute shopping trips by having all your materials ready ahead of time. Here’s a list.

- 1-1/4-in. drywall screws

- Drywall

- Ring-shank drywall nails