Synthetic or Felt Roofing Underlayment- Which is Better?

Prospectors during the California gold rush covered the roofs of their temporary shacks with roofing felt, also known as felt paper or tar paper. Fast forward 170 years and roofing felt is still the most popular roofing material (now used as an underlayment) being installed today. That, however, may be about to change. In the next couple years it looks like we may reach a tipping point where more homes in the United States will be covered with synthetic underlayment than with roofing felt. So what is this synthetic underlayment, how is it different from roofing felt, and why are builders making the switch?

What is Roofing Felt?

To understand why synthetic underlayment might replace roofing felt, you have to know what roofing felt is. Roofing felt is essentially a polyester or fiberglass fleece that is soaked in some waterproofing agent. It is available in two thicknesses, 15 pound and 30 pound. Those numbers are a reference to how much 100-square feet of the paper used to weigh back in the early days of its use. The actual weight-per-square foot these days is actually less than the label says, but the 15 pound. and 30 pound. moniker stuck. Roofing felt typically comes in 36-inch wide rolls.

What is Synthetic Underlayment?

Different types of synthetic underlayment have been around since the early 2000’s. Most synthetics are woven or spun from either polyethylene or polypropylene. While the ingredients are similar, the manufacturing process and thickness of each type of underlayment can be fine-tuned to produce different properties, such as exposure time and walkability. One way of comparing synthetic underlayment is by weight, similar to the way that felt is compared. Instead of pounds-per-100-square-foot, synthetics are rated by grams-per-square-meter (GSM).

Price: Synthetics vs. Felt

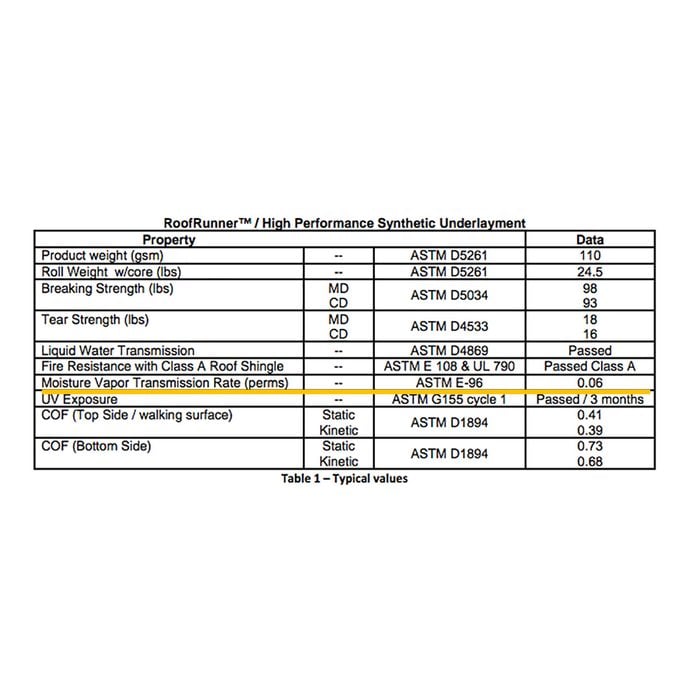

The price of synthetics is based on weight and performance. Heavier products typically have more high-performance qualities built in, like improved walkability, durability, and longer exposure times. The cost of the thinner synthetics right now is comparable to a high quality 15 pound felt, but still more expensive than the cheaper felt. Thicker synthetics cost about 30%-40% more. Some thinner products are actually cheaper than felt, but Dale Walton, a Product Manager at CertainTeed, warns against going too thin. CertainTeed sells two synthetic products, RoofRunner which has a GSM of 110 and DiamondDeck which weighs 185 GSM. Dale said that their testing has shown that products with a GSM less than 110 are prone to tear outs and puncture holes from imperfections in the decking surface.

Synthetic Comes in Larger Rolls

Roofing felt rolls are 3-feet long and cover about 400 square feet. Synthetic underlayment rolls are 4-feet long and cover closer to 1000 square feet. It does not take a roofing scientist to figure out that a roof can be covered faster with larger rolls, and more coverage per roll translates to fewer trips fetching additional product.

Rolls of Synthetic are Lighter

The thing about roofing products is that they can be an absolute pain to get up on the roof. So anytime the materials needed for roofing can be lighter, it is a good thing. A very good thing, some might say.

More Flexible In the Cold

Roofing felt gets stiff and wants to retain its curl when the mercury drops. Most synthetic products have no such issue.

Synthetic Underlayment Is Now Safer

When synthetics first came out, one of the main complaints was that they got slippery when wet. Exactly the opposite is true these days. Some types of synthetic underlayment actually gets a little tacky when wet. Improved walkability alone is the reason many roofing contractors have made the switch from felt.

Fastening is Critical

An installer needs to follow the directions when installing synthetic underlayment, just like any other building material. Most synthetic manufacturers require the product to be fastened with capped nails, not staples. This is especially true if the product will be left exposed for any length of time.

Low Perm Rating

Most synthetic products have a perm rating much less than felt. This means that any moisture in the attic will NOT be escaping through the roof itself, making proper attic ventilation very important. And it’s best to check with the manufacturer to confirm their product is recommended on a “hot roofs.”

Types of Roofing Material Matter

Not all types of roofing can be installed over all types of synthetic underlayment. When installing any kind of roofing other than asphalt (steel, wood, tile, etc.), make sure the synthetic you install is compatible.

Don’t Skip Peel and Stick

Synthetic underlayment still needs to be used in conjunction with peel and stick (aka. self-adhering or ice and water) underlayment, which are required to cover overhangs, valleys and wall intersections. There are synthetic peel-and-stick products available, but they are not as widely used because they are seen as most contractors as cost prohibitive. Roofing codes vary from region to region; make sure to check with your local building officials on the peel and stick requirements in your area.

So What’s Next?

When asked about the future of synthetic underlayment, Ron Heather, vice president of Roof Depot, had this to say:

“Ten years ago we wouldn’t have touched the stuff. Ten years from now, when the prices are the same or less than felt, we will use nothing but synthetic. It’s safer to work with. The installers love working with it. It’s just a superior product all the way around.”