How to Strengthen Floor Joists From Beneath

Updated: Jan. 03, 2023Fix bouncy floors by adding bridging, adding a layer of plywood or adding a wall or beam.

- Time

- Complexity

- Cost

- A full day

- Beginner

- $51–100

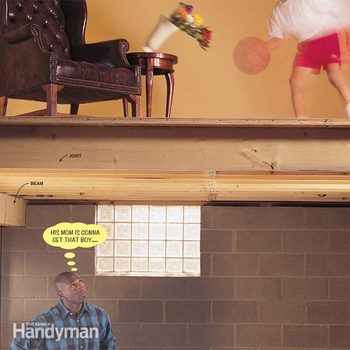

Test the floor before you start

Years ago, while working as a carpenter, I helped stiffen a bouncy floor by nailing a new 2×10 to each of the 2×10 joists that supported the floor. It was a complex, expensive job: Working in the unfinished basement below the bouncy floor, we had to remove the plumbing and electrical lines running through the joists and then rerun the lines after the new 2x10s were in place.

It worked. By doubling up the joists, we cut their “deflection” (the distance they would bend under weight) in half. The floor hardly bounced at all and the client was happy. But I know now that we could have made that floor just as stiff—even stiffer—with a lot less trouble and expense.

This article will show you three better ways to take the bounce out of a floor. You can stiffen the floor in just one room, or in as many rooms as you like. The methods we’ll cover make floors stiffer, but not necessarily stronger. If your floors are bouncy and also noticeably sagging, they probably are too weak. You may need the help of a structural engineer to solve this problem, but begin with a call to your local building inspector, whose advice is free.

You don’t need any special skills or tools to stiffen your floors, and all the materials are readily available at home centers. The fixes we’ll show work for both solid wood joists and wood I-joists. But there is a catch: For two of the three fixes we show (Solutions A and B), you need access to the floor joists from below. That means having an unfinished basement, a basement with an easily removed suspended ceiling or an accessible crawlspace. Otherwise, you’ll have to tear off the drywall or plaster. The third fix (Solution C) will work even if the ceiling is finished.

Joists, the primary structural member in a floor, rarely span the entire width of a house. Instead, a wall or beam usually supports them near the middle. And if you have a beam, you have to make sure that it’s not too weak before you beef up the joists.

Here’s a simple test: Go to the exterior wall opposite the beam. Stand on your tiptoes, then drop hard onto your heels. You should feel almost no bounce here. Next, stand about halfway between the exterior wall and the beam. The tiptoe-drop should cause the biggest bounce here.

Finally, stand near the beam. Any bounce you can cause here should be small, similar to what you felt along the exterior wall. If the result is more like what you felt in the middle of the floor, the beam below is either undersized or not supported sufficiently by posts. Solve this problem first, by asking your local building inspector about correct beam sizing.

Solution A: Add bridging

Bridging, or “X-bracing,” allows joists to share weight. As a footstep falls on one joist, some of the force is transferred to neighboring joists. Even if your joists already have a row of bridging at the center of the span, adding a row on each side of the existing bridging will stiffen the floor.

This solution doesn’t make the floor as stiff as the other solutions, but since it’s relatively easy and inexpensive, you might want to try it first. If you don’t get the results you want, you can still try a different solution.

Begin by checking the original bridging. If any of it is loose, add some nails or screws to secure it. Add a row of new bridging at both of the one-third points of the span. If your joists span 12 ft., for example, place bridging 4 ft. and 8 ft. from the foundation wall. If there is no bridging in the center of the span, install a row there as well.

Metal bridging is available at home centers in lengths to fit between joists that are centered 16 in. or 24 in. apart.

Solution B: Add a layer of plywood

As a joist bends downward, the lower edge bends slightly to one side or the other. A layer of 3/4-in. plywood firmly fastened to the undersides of joists helps prevent this side-to-side bending and stiffens the floor.

For this fix to work well, the upper edges of the joists must be solidly fastened to the subfloor above. Squeaks in a floor usually mean that the subfloor has loosened from the joists. If your subfloor is plywood and has few or no squeaks, you’ll get excellent results. If your house is more than 30 years old, your subfloor is probably made from individual boards. You can still get good results with a subfloor like this if the boards fit tightly together. But if there are wide gaps between the boards or the floor is very squeaky, this fix will be less effective.

A rock-solid bond between the new plywood and the undersides of the joists is crucial; you’ll use lots of screws and construction adhesive. Begin by sanding the underside of each joist with coarse sandpaper (60- to 80-grit). Two or three passes with the sandpaper are enough to leave a rough, clean surface for the adhesive.

Then glue and screw the plywood to the joists. The plywood runs parallel to the joists, not across them. The 8-ft. long sheets are centered on the span, leaving the ends of the joists exposed.

If you want to attach drywall to the ceiling later, you’ll have to install strips of 3/4-in. plywood or 1×4 to the undersides of the exposed joist ends. You can use CDX plywood or BC plywood, which has one smooth side. Be sure the construction adhesive you use is recommended for subfloors.

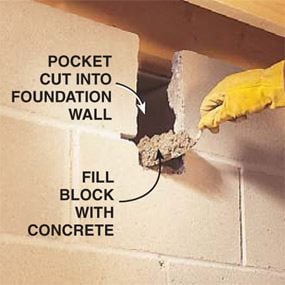

Solution C: Add a wall or beam

The longer the distance a joist spans without support, the more it will flex. By building a wall under joists, you divide the span. The floor above will be stiffest if you place the wall in the middle of the joists.

If you build a wall to support joists, be sure to place a stud directly and tightly under each joist. If the wall will have a doorway, place a double 2×6 header above the door’s rough opening.

A beam will leave your basement wider open, but installing a beam means a lot of work. A beam made from two 2x12s should be supported by adjustable metal posts or 4×4 wood posts every 10 ft., and you’ll have to pour footings for these posts to rest on.

If you have I-joists, be sure to add a 2×4 block between the wall or beam and the subfloor at each joist.

Required Tools for this Project

Have the necessary tools for this DIY project lined up before you start—you’ll save time and frustration.

- Hammer

- Safety glasses

- Stepladder

- Tape measure

Required Materials for this Project

Avoid last-minute shopping trips by having all your materials ready ahead of time. Here’s a list.

- 1-1/2-in. drywall screws

- 1-3/8-in. joist hanger nails

- 16d nails

- 2x12

- 2x4

- 2x6

- 3/4-in. plywood

- 60 grit sandpaper

- Construction adhesive

- Metal bridging