How to Install a Glass Block Shower

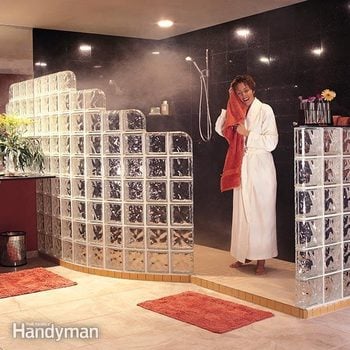

Updated: Aug. 22, 2022A curved wall creates a unique bath area

A glass block wall installation can turn an ordinary bathroom into a dramatic showpiece. Step-by-step photos and clear instructions show how to do it.

- Time

- Complexity

- Cost

- Multiple Days

- Advanced

- $501-1000

About glass block

Molten glass was first injected into glass block molds in 1937, and glass block has been a staple of contemporary architecture ever since. Although other building fads come and go, glass block continues to capture the imagination of designers, builders and homeowners.

The smooth, impervious nature of glass block makes it a fantastic substitute for ceramic tile in a shower. With its patterns and sparkle, the block itself is beautiful, and it allows natural light to flood through the walls into the shower.

Before you begin, stock your tool belt with plenty of patience. Glass block work is a skill that’s very aggravating to master. Blocks can’t be cut or trimmed, and their nonabsorbent nature makes mortar work especially tough. But if you don’t try to rush the job, your work can look as good as any professional’s.

A note on installing new bathrooms: Before you run out to buy a truckload of glass block, be aware that converting a bedroom into a bathroom requires extensive work beyond the plumbing. You may have to reroute heating ducts, eliminate existing windows, shift electrical outlets and remove possibly load-bearing interior walls. Run the design by a building inspector to get the necessary permits and inspection schedule. One other warning: If you plan on taking long showers using two shower heads, you might need another 40-gal. water heater.

Editor’s Note: Learn more information on building the shower base.

Glass Block Bathroom Before and After

A shower the size of this one won’t fit in an average-sized bathroom. Ours was made possible by stealing the bedroom of a college-bound lad. His loss became his parents’ luxury!

Glass block basics

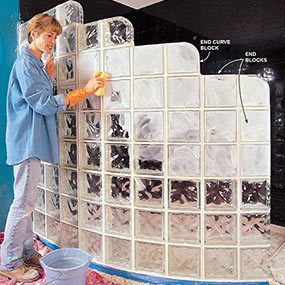

This shower uses the most common, widely available style of glass block: the 8 x 8-in. “Decora” pattern manufactured by Pittsburgh Corning. We used two types of specialty blocks for the ends and the outside corners of walls. End blocks have rounded profiles on one edge; end curve blocks have two rounded edges and one rounded corner (see Photo10). The blocks have a nominal dimension of 8 x 8-in., which means that the actual block is a bit smaller. When 1/4 in. of mortar is added, the dimension of the block plus mortar is 8 full inches. Because blocks can’t be cut, you need to carefully consider the length and width of new and existing walls well before pursuing the project. Planning the height and width of your shower is absolutely critical, especially if you’re going to be filling the space between two walls or between the floor and ceiling. Because our shower didn’t reach the ceiling and wasn’t contained by walls, our design was very forgiving.

Check online or at local home centers for the hardware, mortar and block for this project. You can also call a brickyard. It’ll either sell glass block or know who does. Your retailer will help calculate the amounts of mortar, block and hardware you’ll need for your project as well as stock the pro-quality tools required.

The job will go much smoother if you buy a few of the tools used by the pros. You’ll want a brick trowel, a mortar joint striking tool and a small plastic mortar-mixing box with a hoe. Good 2-ft. and 4-ft. levels are essential to keep the blocks level and plumb as you set them.

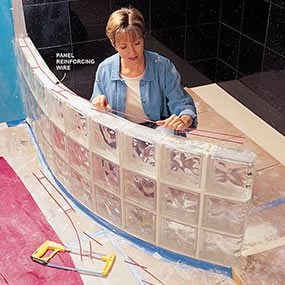

Lay out the glass block grid on the floor

To get a feel for the size and design of the finished walls, we used a chalk line to snap a full-scale grid of the 8-in. block wall on the floor. It helped us establish the stair-step pattern on the curved wall and made it easy to count each type of block needed for the project. Counting the rows also told us the quantity of panel anchors, spacers and panel reinforcing we needed. When you’re planning the overall size of the glass block walls, keep in mind that the 8-in. dimension only allows for one mortar joint per block. You have to add another 1/4 in. for each wall and ceiling joint. Make 8-in. marks on the wall to establish the height for each row (Photo 2). Plastic spacers don’t work on curved walls (for alternatives, see “Glass Block Hardware,” below). Special, but spendy, curved glass blocks or 4 x 8-in. blocks are available for tighter curves, if you need them.

Build and tile the shower base

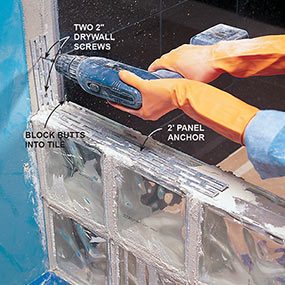

We decided to tile the entire shower base and walls before starting on the glass block. That way, tile on the walls that would meet the glass block could be rough-cut to width, because we ended the tile behind the block (Photo 9). The block butts into the tile and eventually the seam will be sealed with a bead of clear silicone caulk. On the floor, in the dry-off area, we could also rough-cut tile that would run partially under the glass block wall. The advantage of this method is that tiling goes quicker and easier if there aren’t any walls to walk around. However, doing the tile first means having to protect it while you do the block work. Use masking tape to hold cardboard together and to cover any nearby tile.

Glass Block Hardware

All the hardware you need to build glass block walls will be available wherever you buy your glass block.

Panel Reinforcing: It looks like a galvanized wire ladder, and you’ll need to lay it on top of every other row of block before applying the mortar. Panel reinforcing ties the rows of block together and strengthens the whole wall.

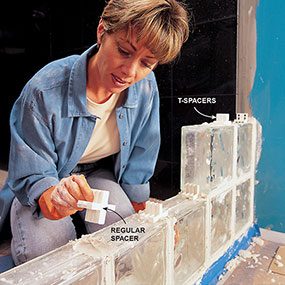

Spacers: Building straight walls is much easier because you can use plastic spacers made specifically for glass block. Use the T-shaped spacers for spacing glass blocks from adjoining floors and walls. Cut one leg from T-shaped spacers to make L-spacers for spacing corner blocks from walls, ceilings and floors. Use regular spacers for block-to-block intersections. Manufactured block spacers won’t work for curved walls. Use carpenter’s pencils or 1/4-in. plywood spacers as temporary guides. Remove them before striking joints, then tuck mortar into the voids.

Panel Anchors: These metal straps tie the block walls to existing walls and are installed every second row.

Mix a half-hour’s worth of mortar at a time

When you’re learning the ropes, mix just a couple of coffee cans’ worth of mortar at a time. Add enough water to the mortar so that it will slowly slide off the trowel when you hold it vertically. The pros will put an accelerator into the mix to speed up the setting time, but rookies should play it safe and use the extra time to set, level, plumb and adjust the blocks.

Wear rubber gloves when working with mortar, and safety glasses to avoid accidental splashes in the eye. Constantly work the mortar mix with the trowel to keep it smooth and consistent. Don’t do more than two rows of block at a time, or the weight of the top rows will cause mortar to squish out of lower joints. (After an hour or so, the mortar will harden enough to permit another couple of rows.) Let the mortar sit about a half-hour (or until the mortar starts to stiffen) before striking the joints with the striking tool. Then go over the whole surface with a soft brush to remove loose chunks. Wait another half-hour before smoothing mortar joints with a sponge. After the mortar dries to a haze on the blocks, polish the block with a clean, dry towel. You don’t have to complete all these steps before starting to set other rows. While you’re laying more block, pause occasionally and go back to perform these tasks on previous blocks. Above all else, continually check all blocks to be sure they’re aligned, plumb and level.

When your shower wall is done, wait a week, then apply a high-quality silicone grout sealer to the shower side of the wall to prevent mildew and stains from ruining the appearance of the mortar. You can use the shower in the meantime—a few showers that week won’t harm the grout.

Required Tools for this glass block bathroom project

Have the necessary tools for this DIY project lined up before you start—you’ll save time and frustration.

- Bucket

- Caulk gun

- Cordless drill

- Hacksaw

- Knee pads

- Level

- Rags

- Safety glasses

- Trowel

- Tuckpointing tool

Required Materials for this glass block bathroom project

Avoid last-minute shopping trips by having all your materials ready ahead of time. Here’s a list.

- 2 1/2-in. galvanized screws

- Glass block

- Mortar

- Panel anchors

- Plastic spacers (for straight walls)

- Reinforcing wire

- Shims

- Silicone caulk

- Tile sealant

- Tiling sponge