Tips for Better Drywall Taping

Updated: Feb. 06, 2023Simple tricks for fast, flawless drywall finishing

Eliminate as many hard-to-hide butt joints as you can

To hide “butt joints” (where two non-tapered ends of drywall meet), you have to build up a hump of joint compound that’s very thin and wide. This is time consuming and difficult to do well. So if you’re a novice drywall finisher, avoiding butt joints is smart.

The best way to avoid butt joints is to use sheets of drywall that are long enough to cover entire walls and ceilings. As a result, you’ll have only tapered joints to finish. Drywall sheets are commonly available in 8- and 12-ft. lengths, and specialty suppliers carry 14-ft. sheets.

If your ceiling is longer than 14 ft., you can’t avoid butt joints. But you can avoid butt joints on a wall that exceeds 14 ft. Simply hang the sheets vertically rather than horizontally. That way, you’ll have several tapered joints to cover, but no butt joints. Hanging drywall vertically is slower than hanging it horizontally because you have to make sure the tapered edges fall at the centers of studs. Cut the first sheet to width so the tapered edge lands on the center of a stud. After that, the edges of each sheet should fall perfectly on studs. If you run into misplaced studs, nail 2x2s to them. If you have 9-ft. ceilings, call a drywall supplier to find 10-ft.-long sheets.

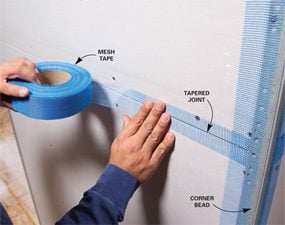

Use mesh tape, not paper

Pros use paper tape to strengthen joints. But in less-skilled hands, paper tape can ripple, slip out of place or trap air bubbles. If you push too hard as you embed paper tape, you’ll squeeze out all the joint compound behind it and the tape will peel off later. Adhesive-backed mesh tape eliminates all those glitches. Just stick it in place and it stays put, leaving you free to concentrate on spreading a smooth coat of mud. And since it doesn’t require an underlying layer of compound, mesh allows for a thinner buildup over butt joints and repairs. You can use mesh anywhere except inside corners.

But mesh tape has one weakness (literally): It’s not as strong as paper. To compensate, you have to cover it with setting-type joint compound, which is stronger than premixed compound (see tip below). Apply mesh tape no more than a few hours before you’re ready to cover it. Left uncovered, it will eventually fall off.

Fill joints faster with setting-type compound

Mixing up setting compound is a messy nuisance, but it’s worth it. Setting compound has three key advantages over premixed versions: It allows you to use mesh tape, it hardens fast and it shrinks much less. Quick hardening and low shrinkage make setting compound perfect for deep filling. A thick layer of premixed compound takes days to dry and shrinks. You’ll need several coats to fill the depression, and the more layers you add, the harder it is to get smooth results.

For small repair jobs, you can mix setting compound with a paint paddle. For larger jobs, use a corded drill with a 12-in. long mixer attachment. Don’t buy a 24-in. mixer unless you have a powerful 1/2-in. drill. The key to a smooth, chunk-free mix is to let it stand for about five minutes after the initial mixing. That lets the chunks absorb water before final mixing. Setting compounds have different hardening times, ranging from 5 to 210 minutes. The 45- or 90-minute versions are best for most jobs. Be sure to choose a “lightweight” setting compound. Other versions become so hard that sanding away mistakes is nearly impossible. Even the lightweight versions are harder to sand than premixed compound, so it’s best to use setting compound for the first coat and premixed compound for later coats. Be sure to clean tools before the setting compound hardens.

Coat inside corners faster and smoother with a corner knife

It takes a steady hand to embed tape in inside corners with a standard drywall knife. One little slip of the knife and you’ll gouge one side while you’re smoothing the other. An inside corner knife not only eliminates that problem but does the job faster. Outside corner knives are also available, but we don’t recommend them, since corner bead makes smoothing outside corners almost foolproof.

Apply compound and place the tape as usual. Then load some mud onto the corner knife to lubricate the knife and leave a thin coat of compound over the paper. Start at the top of the corner and drag the knife down to about 16 in. from the floor. Then start at the floor and drag upward. Ease off when you reach the area that’s already smooth. You may have to repeat this process two or three times to fully embed the tape and create a smooth, straight corner. A corner knife doesn’t ensure straight corners, so reinforced corner tape is a good idea. Use a corner knife for the first coat only; after that, coat one side at a time, allowing one side to harden before you coat the other.

Dunk paper tape to avoid drywall tape bubbles and bulges

Paper tape can ripple, slip, bulge and bubble. But you can minimize these problems by dropping it into a bucket of water. Wet paper tape is more pliable than dry tape, so it traps fewer air bubbles behind it. Water also makes the paper slick, so your knife slides over the tape without creating ripples or creases. Wetting doesn’t eliminate the squeeze-out problem, so you still have to be careful to leave a thin layer of mud between the tape and the drywall. Don’t let the tape soak—that will soften the paper and make it more susceptible to scuffs and tears.

Keep corners straight with reinforced tape

Inside corners are tough to keep neat and straight. Unless you have a very steady hand, your knife can wander as you embed the tape. And if you create a wavy corner with the first coat of mud, creating a straight corner with subsequent coats is almost impossible.

The solution is to use tape that’s backed with metal or plastic strips (available in100 ft. rolls at home centers). This tape is especially helpful on odd-angled corners, which are very hard to keep straight. It’s still possible to create a wavy corner if you push too hard, so apply light, even pressure as you smooth the joint compound. The strips reduce ripples and bubbles too, so there’s no need to wet the tape. Don’t overlap the tape where inside corners meet the ceiling. Instead, cut the tape short to avoid a triple-thick buildup of tape.

Flatten bumps and bulges between coats for less sanding later

Everyone hates the dust cloud raised by sanding drywall. And the best way to minimize sanding later is to knock down high spots between coats. Left alone, these high spots will grow higher and wider (and harder to fix) with each coat. Don’t worry about low spots; subsequent coats will fill them.

If you used setting-type compound, inspect the joints before the compound has hardened completely. Run a 12-in.-wide knife over every joint. The blade will scrape off small ridges and nubs. More important, it will act as a straightedge, revealing larger bumps and bulges. When the compound is about the consistency of a bar of soap, you can easily shave down bulges without gouging. You can sand and scrape setting compound after it’s completely hard, but that’s more work.

With standard joint compound, however, it’s best to let each coat dry completely before inspecting, scraping and sanding. The surface of partially dry standard compound may be firm while the underlying material remains soft and easy to gouge.

Create a smooth surface with a knockdown knife

Feathering out a butt joint or skim-coating a whole wall is difficult because your knife leaves ridges on the broad surface—and touching them up often creates even more ridges. The solution is a “knockdown” knife. With its soft rubber blade, this squeegee-like tool floats over the surface, flattening ridges without creating new ones.

A knockdown knife won’t scrape down big bulges or fill wide depressions, so make the surface as flat as you can with a 12- or 14-in. metal knife first. Then drag the knockdown knife gently over the surface in one continuous pass. Apply light, even pressure and don’t stop or hesitate. On a butt joint, you’ll have to make two or three passes to smooth the whole surface. You can make more passes if necessary, but stop before the compound starts to harden. Although the rubber blade is soft, it can still make a mess of partially hardened compound. Knockdown knives are available in 18- and 22-in. widths at drywall suppliers and some home centers and hardware stores. A 22-in. version is best for butt joints. To order one online, search for “knockdown knife.”

For smooth walls faster, finish with topping compound

Any type of joint compound can hold tiny air or water bubbles that leave pockmarks on the surface. But you’ll get fewer pockmarks with “topping” compound. Topping compound looks just like other versions of premixed joint compound, but it has a creamier texture. That smooth consistency makes it easier to feather out and creates a glossy surface with very few pockmarks. It also shrinks less as it dries. With all these advantages, topping compound helps you get to the final sanding stage with fewer coats and fewer fixes between coats. And when the time comes, you’ll find that topping compound is the easiest compound to sand. Topping compound has poor bonding strength, so don’t use it for the first coat.

Keep crumbs out of your mud to prevent scars

You can’t create a smooth surface using joint compound that has crumbs of hardened compound in it. One tiny chunk clinging to your knife will leave a scar across the whole joint. Cleanliness is the key to keeping your mud free of chunks. Scrape down the insides of the bucket every time you scoop out mud. Then wipe the sides clean with a wet rag. At the end of the day, cover the compound with a thin layer of water. The water will remain on top of the compound, so you can pour it off before you use the remaining mud.

Never dump leftover compound from your mud pan back into the bucket; just throw it away. To keep the pan and tools clean between uses, scour them with an abrasive sponge or immerse them in water. Setting-type compound will continue to harden even under water, so wash tools as soon as you’re done. Never send large amounts of setting compound down the drain—it can plug pipes.

Required Tools for this Project

Have the necessary tools for this DIY project lined up before you start—you’ll save time and frustration.

- Corded drill

- Drywall saw

- Knockdown knife

- Mud pan

- Rags

- Screw gun

- T-square

- Taping knife

Required Materials for this Project

Avoid last-minute shopping trips by having all your materials ready ahead of time. Here’s a list.

- Joint compound

- Mesh tape

- Paper tape

- Reinforced corner tape

- Setting-type compound

- Topping compound