Connecting to Concrete

With a little know-how, it’s as easy as other fastening jobs.

Fastening something to concrete, brick or stone might be intimidating if you haven’t done it before. But I’ve found that the toughest part is drilling the hole. After that, it’s just like fastening to any other material. So don’t be intimidated! With these tips, you’ll be able to attach just about anything to concrete.

Caution: Silica dust can damage your lungs. Always wear a respirator when you’re drilling or cutting concrete or masonry.

On This Page

What’s the Difference Between a Hammer Drill and a Rotary Hammer?

Hammer Drills

Hammer drills often come as a combination driver with a drill, drive and hammer setting. In the hammer setting, a pair of grooved discs rotate, making the chuck slam forward and back as the chuck rotates. This hammering force makes the drill bit chip into the concrete as it spins.

More pressure, more progress

When you’re using a hammer drill, more force equals faster progress. But watch out, these bits can break — ease up if it starts to bend!

Dial in the RPM

With a hammer drill, I find that slower RPM (revolutions per minute) means slower drilling, while higher RPM doesn’t mean faster drilling. The sweet spot for me is medium-high RPM. My hammer drill has two speed settings, so I use the high setting and nudge the speed up until I find that sweet spot where the bit proceeds at a steady pace.

Rotary Hammers

Rotary hammers are the hammer drill’s big brother. The motor rotates the bit and moves a piston back and forth, which gives the tool more pounding power. Many rotary hammers are multifunctional, adding drill and hammer to the basic rotary hammer function, making them far more useful.

If you have lots of drilling to do, a rotary hammer will cut your labor considerably. You can buy a rotary hammer starting at about $100.

Let the tool do the work

Unlike with a hammer drill, you don’t need to put your weight behind a rotary hammer. Too much force reduces the effectiveness of the piston motion. Apply just enough pressure to make steady progress.

My Go-To Concrete Fasteners

You’ll find a dozen fastener choices at the hardware store, all suited to different tasks. The most important thing is to drill the proper hole size for your fasteners.

Concrete Screw

I choose concrete screws for most fastening jobs because they’re easy to use, strong and removable. They range in diameter from 3/16-in. to 3/4-in., and in length from 1-1/4-in. to 6-in.

Pro Tip: An impact driver is my go-to tool for driving concrete screws. It’s the only way to go!

Plastic Anchor

Plastic anchors work the same in concrete as they do in drywall — press the anchor into the hole and it expands for a snug fit as you drive a screw into it. Plastic anchors are the cheapest option. They’re best for light-duty tasks like hanging small pictures and shelf brackets.

Sleeve Anchor

Used for heavy-duty fastening or hanging, sleeve anchors are permanent, really strong and less expensive than large concrete screws. They can be used in any concrete or masonry and have either a screw head or a nut to tighten. The sleeve expands as you tighten the nut for a firm grip.

Wedge Anchor

Wedge anchors provide the strongest connection for demanding jobs like fastening structural hardware to concrete. Hammer the anchor into the hole, then turn the nut to lock the anchor in place. Don’t use wedge anchors in brick, block or mortar joints. The force may cause cracking.

Concrete Fastening Tips From the Jobsite

Go deep

Drill your hole at least 1/4-in. deeper than the length of your fastener (1/2-in. deeper for fasteners 3/8-in. or larger in diameter). This ensures that your fastener won’t bottom out because of dust or other debris in the hole. If your drill doesn’t have a depth gauge, wrap a tape flag around the drill bit so you know how deep to go.

Fix a strip-out

So you’ve drilled your hole and for some reason your fastener doesn’t grab. Before throwing in the towel, try these options:

- Add a Wire. Push a copper wire into the hole, then drive your concrete screw.

- Drill a Bigger Hole. Upsize the hole and drive in a bigger fastener. You may also need to drill out the hole in the parts you’re fastening.

Shoot nails into concrete

If you have a lot of concrete fastening to do, consider a powder-actuated tool. It uses a gunpowder load to shoot a special nail into concrete. It’s the quickest masonry fastener available and costs as little as $25. Before you use one, go to familyhandyman.com and search for “powder actuated tool” to get the full story.

Control the dust

Concrete contains crystalline silica, which can lead to serious health issues. Always wear a respirator when drilling into concrete, but don’t stop there. A vacuum nozzle close to the action prevents most of the dust from ever going into the air.

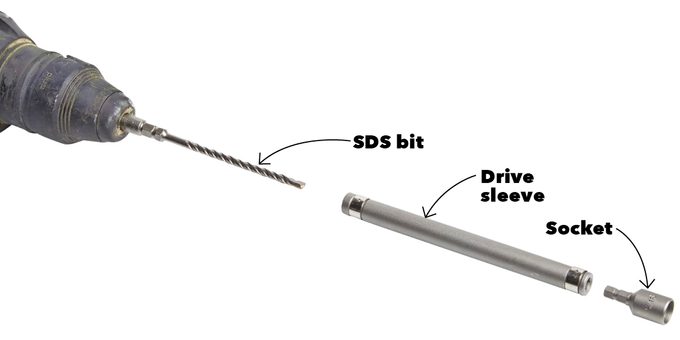

Fasten faster with a bit kit

To speed up drilling and driving, use a special kit like this Bulldog Anchor Drive Installation Kit by Bosch. Many brands make a similar installation tool; this one costs about $40. It slips over an SDS (slotted drive shaft) bit, letting you drill and drive fasteners.

If you hit a hard spot, move on

When you’re drilling concrete, sometimes you’ll hit something that the bit can’t easily penetrate, typically a rock or rebar. Sometimes you can work through it, but it’s best to try a different spot. Even if you get through it, your fastener will hit it too and likely shear off as you’re driving it.

Drill wood with a masonry bit?

When fastening wood to masonry, some people drill through wood with a standard bit, then switch to a masonry bit. Switching isn’t worth the hassle. A masonry bit isn’t the best for wood, but it will do the job without harming the bit.

Clean out the hole

When you drill a hole, dust settles to the bottom and clings to the sides of the hole. The dust could keep your fastener from embedding all the way or cause a sleeve or wedge slip. Use a vacuum and a copper fitting brush to remove all the dust.

Stay away from the edge

A good rule of thumb is to keep an anchor away from an edge a distance of at least 12 times the diameter of the anchor. For example, a 1/4-in. anchor requires a minimum distance of three inches from an edge. Don’t use a wedge anchor in this situation — its outward force could cause a blowout.

Do I fasten to mortar or the block/brick?

Drill into mortar if you’re hanging a picture frame or lightweight holiday decorations. Mortar is a lot easier to drill into. It’s more prone to crumbling, but it’s easier to patch. When you’re hanging heavier objects like a TV, it’s better to fasten directly to the brick or block. The material is harder but still brittle, so avoid wedge anchors.

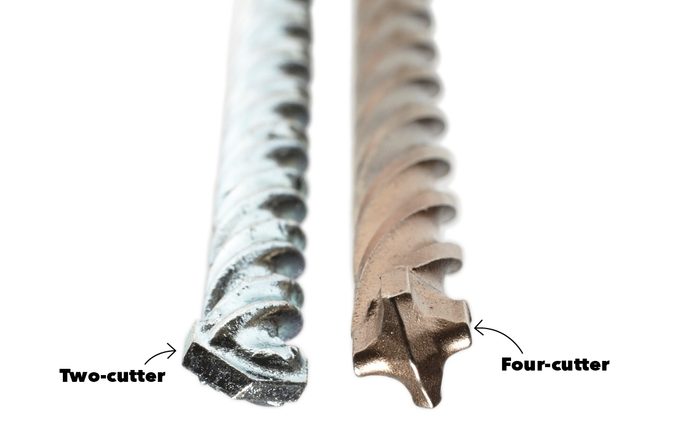

For a smoother ride, use a four-cutter bit

Two-cutter bits work fine, but four-cutter bits are better. Four-cutter bits are available at home centers for about 20 percent more than two-cutter bits. Four-cutter bits last longer, cut smoother and easier and are less likely to twist the drill out of your hand if you hit a hard rock or rebar.

Don’t bother with masonry nails

You’ll likely still find a dusty box of masonry nails tucked away at the hardware store. Leave it there. Masonry nails aren’t up to the standards of newer fasteners and anchors, and they require more effort than concrete screws.

Clear the flutes

The bit’s flutes carry dust up and out of the hole as you drill, but they can get clogged. When they do, the bit spins without making any progress. To release the dust buildup, just pull the bit out of the hole while it’s spinning. I typically do this every inch or so of depth.