How to Build a Gazebo

Build this airy summer hangout that features fish-scale shingles and decorative trim you make yourself.

Multiple Days

Intermediate

$501-1000

Introduction

A gazebo is a perfect place to entertain and also makes for a striking feature for your yard. One look at this beauty and you'll be picturing it filled with family and friends, celebrating a graduation or even a backyard wedding. We designed this 12-ft. gazebo to include plenty of eye-pleasing trim, from the pattern-cut rails that surround the seating area to the ball-shaped finial atop the cupola. It's easy to build your own gazebo if you follow our special hints, tips, technical illustrations and cutting lists.This Gazebo is Builder-Friendly

This gazebo project is not as difficult as it looks, but it will take you a good deal of time. Think of it as a series of several shorter projects with an end goal in sight for each. You can build all the decorative parts in your garage or shop.

If you have several friends help you with the slab and framing, you can spread these two tasks over several weeks. A project like this would take two experienced carpenters nine working days from start to finish. An intermediate do-it-yourselfer who has built a deck should plan this as a whole summer project.

NOTE: You must have a site that slopes less than 4-in. over 12-ft.; any more than this will require some excavating.

Figuring Out The Slab:

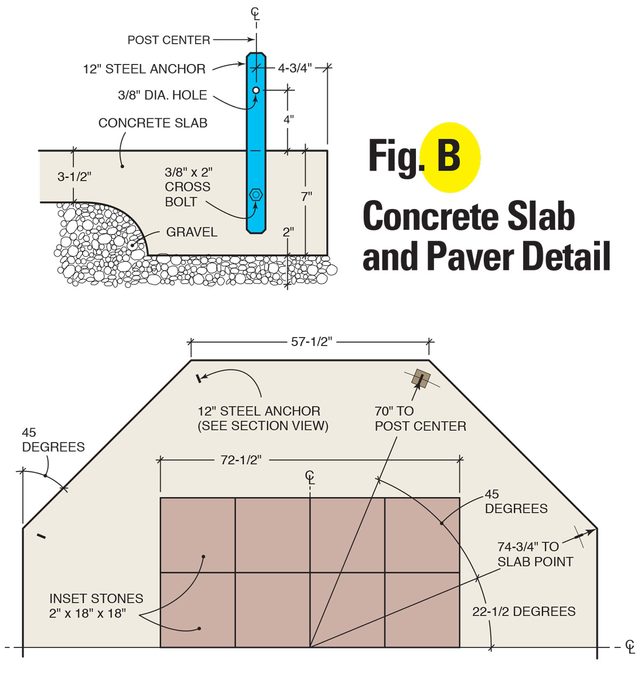

You don’t have to get the slab dimensions perfect, but the closer they come to it the easier things will be later. If you hate doing concrete work, skip this section, photocopy it and give it to your concrete mason. A crew can do the work for about $1,200 while you’re out shopping for lumber or cutting parts (but you can cut the cost to a couple of hundred if you do it!). Closely follow Fig. B (above and below in “Additional Information”) if you decide to pour the concrete slab yourself.

Running an Electrical Conduit

To build your gazebo, begin by driving a two-foot piece of rigid electrical conduit at the intended center of the gazebo. Drive it in 18 inches. Remove the sod with a rented sod cutter. You’ll need to excavate a nine-inch-deep area radiating out about 78 inches from the conduit. After that, you’ll set forms and put in a layer of 1/4-in. gravel to the dimensions shown in Fig. B. The idea is to have the outside foot or more of the slab thicker to support the weight of the structure.

Tips for Building Your Forms

Build your forms after carefully examining Fig. B. Set your circular saw at 22-1/2 degrees and cut eight 2×8 exterior forms with the short side measuring 57-1/2-in. Screw the forms together with three-inch deck screws. Have a friend help you align the forms so the eight corners of the forms are all the same distance from the conduit center. If these measurements are all equal, your slab will be a perfect octagon — get it as close as you can. Drive 3/4-in. x 2-1/2-in. stakes along the outside of the forms at each intersection, level the forms and screw the forms to the stakes.

Now build a square inner form for the patio inlay, 72-1/2-in. on each side. Center it as shown and drive in the stakes on the inside of the forms and screw them together.

Concrete Slab Requirements

The slab will require about 1-1/2-yds. of concrete and four 10-ft. pieces of No. 4 rebar. Have plenty of help (at least three strong backs and two heavy-duty wheelbarrows). Wheelbarrow the concrete and dump it into the forms, lay rebar four inches in along the perimeter, screed the concrete with a straight 2×4, then run the hand float over it. Set your anchors in at the locations shown in Fig. B. Wait till the concrete is firm (you should have to push hard to leave a thumbprint). Smooth it with a steel trowel, cover it with 4-mm clear plastic and let it set for two days.

Additional Information For this How to Build a Gazebo Project:

Project step-by-step (18)

Cut the Posts to Length

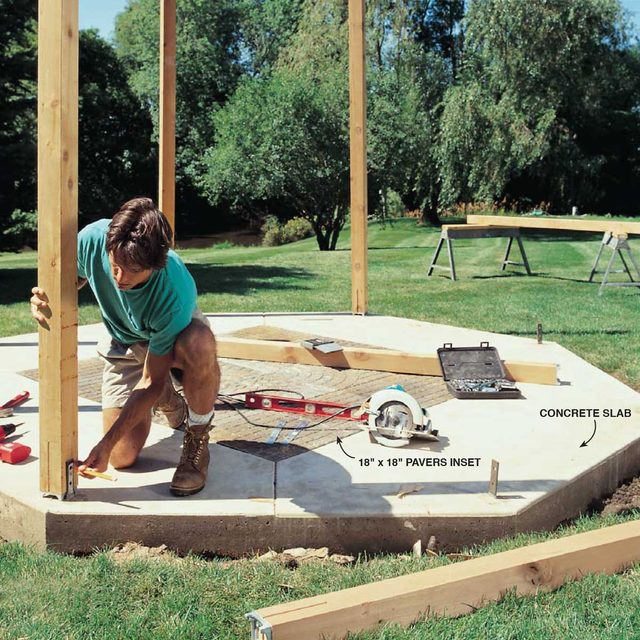

- Bolt posts to the steel strap anchors. Here’s how to do it:

- Make the anchors by cutting 12-in. lengths of 1/8-in. x 1-1/8 in. steel and boring 7/16-in. dia. holes into them as shown in Fig. B.

- Pro tip: You can find steel stock next to the threaded rod at your home center.

- For extra grabbing power for your posts, be sure you put a bolt and nut into the base before you push the steel into the concrete.

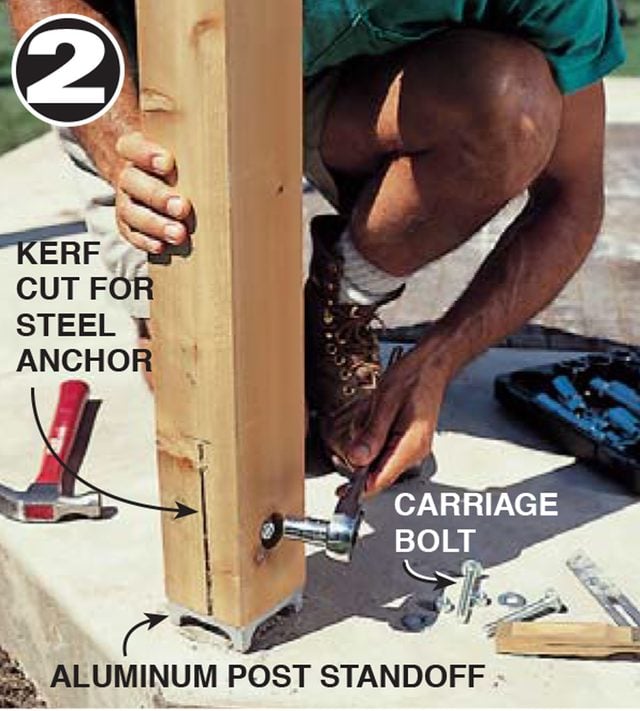

- The 6-in. of steel anchor above the concrete fits into a saw kerf at the base of each post.

- Cut this kerf with a circular saw.

- Pro tip: The blade won’t cut all the way through, so flip the post over to continue the cut in the other side.

- Make the kerf wide enough so you don’t have to struggle to slip it over the steel anchor.

- Before you mark your anchor hole cut your posts to length and bolt them to the steel strap anchors locations, screw the aluminum post standoff to the base of the post.

- Pro tip: These standoffs keep the post elevated for protection against rot.

- Mark the anchor hole locations as shown in photo, then drill a 1-1/4-in. hole 1/2-in. deep on each side of the post, followed by a 3/8-in. hole all the way through.

- Pro tip: The 1-1/4-in. hole recesses the bolt head and nut to make room for the piece you’ll nail over the post later.

- Grab a buddy to help set the post while you push the bolt through the hole and tighten it.

- Once all the posts are in place, cut the 2×6 top plates and screw them to the top of the posts with a pair of 3-in. deck screws.

- Plumb this framework with some temporary braces.

Tighten the Nut

- Tighten the nut onto the carriage bolt.

- Temporarily brace the 4x4s if necessary.

- Be sure you have the standoff screwed to the posts before you mark and drill the hole.

Screw the 2×6 Top Plates

- Screw the 2×6 top plates to the 4×4 posts with 3-in. galvanized screws.

- If your posts are set properly, the top plates should all be the same length.

- Make any adjustments to ensure the posts will all be plumb.

- Use a level to plumb the posts and install temporary bracing.

- Cut and install the post wraps C1 and C2 (in the Cutting List, in additional information above) at this time.

Give the Posts Some Dimension:

- Give the posts some beef and dimension by nailing the cedar wrap to the tops and bottoms.

- Nail the 1×4 (C1 and C2) cedar wrap onto the posts first, then measure this width and rip-cut the wider 1×6 to fit (D1 and D2).

- Nail the wider wrap to the post with 8d galvanized casing nails.

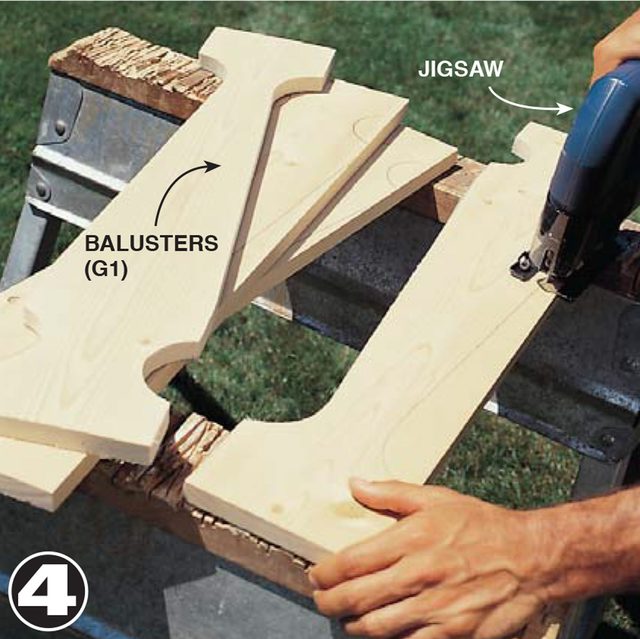

Cut the Balusters

- Cut the balusters and the pickets from 1×6 and 2×6 material. See Fig. C in the attachments above.

- Sand, prime and paint the pieces before installing them.

Set Up and Cut Out the Gingerbread Pieces

- These ornate parts do take time, but there’s nothing difficult about cutting them.

- Use the scale drawing in Figs. C and D to make a full-size template and trace the shapes onto boards.

- Pro tip: Don’t think you have to cut all of them in one day. This is the kind of task you can chip away at by knocking off several pieces every day after work.

- Cut the lower balusters from 1×6 pine and the upper pickets (G2 and G3) from 1×4 pine.

- Use a circular saw for end cuts and a jigsaw for curves.

- Once you’ve finished cutting these pieces, sand the edges and prime and paint them.

Cut the 16 Corner Brackets

- Cut the 16 corner brackets from 5/4 x 9-1/4 in. pine (which is 1-1/8-in. thick).

- Pro tip: Note that there are eight left- and eight right-hand pieces.

- Cut the corner braces (J) from 5/4 (1-1/8 in. thick) pine.

- After you cut the shape, bevel-cut one side with your circular saw set at 22-1/2 degrees.

- Pro tip: Keep in mind that there’s a left and a right corner brace for each post.

- Prime and paint these as well.

- Nail the corner braces to the post and rail with 8d galvanized casing nails after you install the rails, lower balusters, upper pickets and all the cleats.

- Use 4d galvanized casing nails to nail the cleats to the rails.

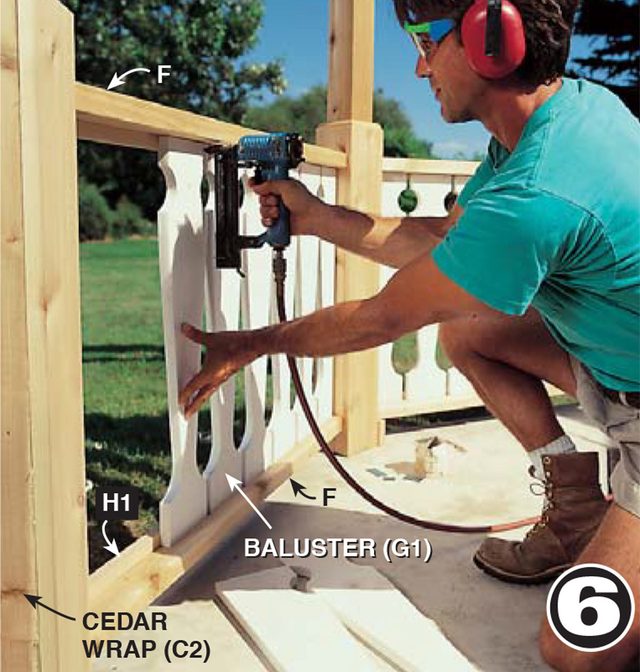

Miter and Screw the Rails and Headers

- Miter and screw the rails and headers to the posts with 3-in. galvanized screws.

- Nail the balusters (G1) to the cleats, which are nailed to the cedar rails.

- Use 1-1/4-in. galvanized nails.

- Pro tip: A power finish nailer is handy here.

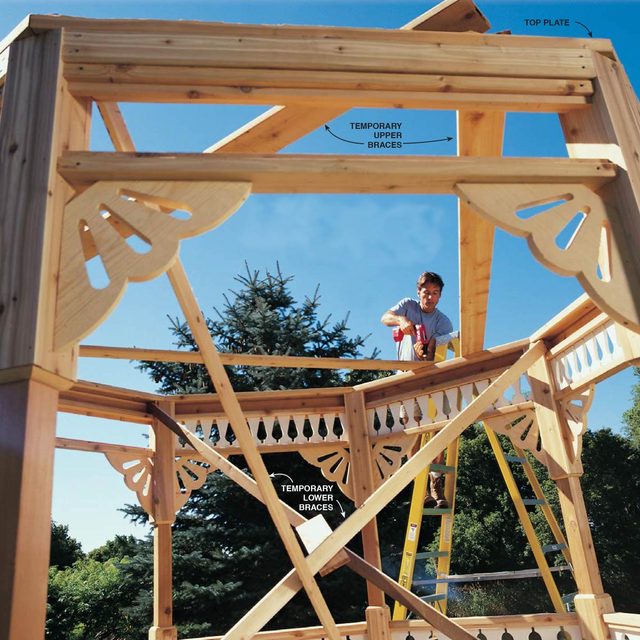

Screw Upper Braces

- Screw upper braces to the top plates (B). These will help stabilize the structure as you assemble the roof.

- Be sure the posts are anchored with braces as well.

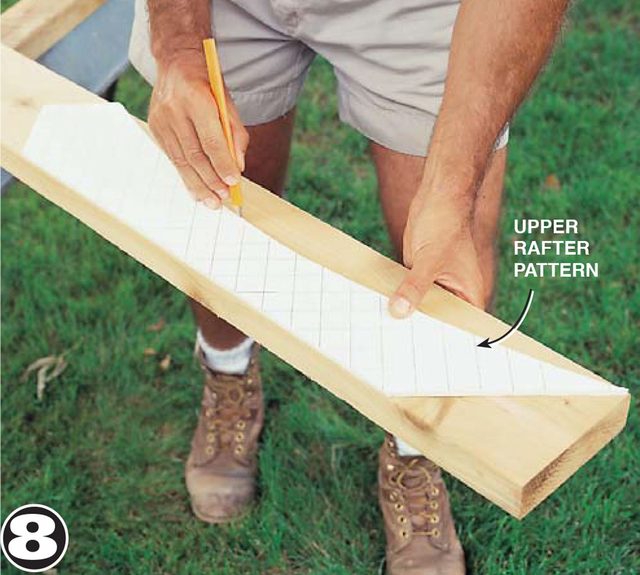

Cut the Cupola Rafters

- Cut the rafters and the curved rafter tail buildups using the information in Fig. F.

- Pro tip: Study Figs. A, E and F in the attachments at the beginning of this article.

- Cut your lower rafters (K1) and screw curved rafter tail buildups (K2) to the ends of the lower rafter.

- Cut the 1×2 inner and outer vertical rafter ties (L and P).

- Notice that these 2×4 outer vertical rafter ties have slots cut in them to slip over the upper and lower rafters.

- You can cut these slots with a table saw or circular saw, working from each end.

- First cut one side with multiple passes and then flip the rafter tie over and cut multiple passes from the other side.

- You’ll get an angled slope at the end of the slot from the roundness of the blade.

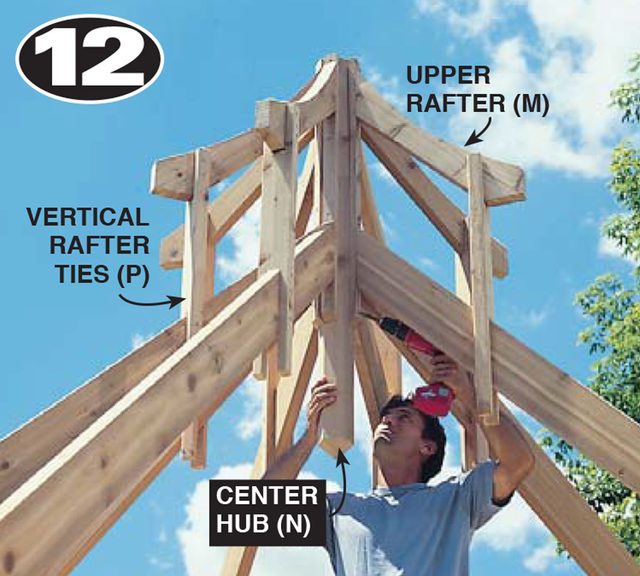

Shape the Center Hub

- Shape the center hub (N) into an octagon.

- Measure in from each side about one inch and cut along this line with your saw bevel set at a 45-degree angle.

- The finished octagon should be about 1-1/2-in. on a side.

Assemble the Rafter Sections Before Hauling them to the Roof

- Lay out the rafter parts (not including the center octagonal piece N) on a large flat area like a garage floor or a driveway (look at the upper left diagram of Fig. A).

- Fasten the upper and lower rafter to the 1×2 (L) with 2-in. screws.

- These rafters run parallel, with a 14-1/2-in. space between them.

- Next screw part P into the sides of the upper and lower rafter so that it’s parallel to part L.

- Build the rest of the assemblies and then mount a pair to the center hub (N; see step 9).

- Follow steps 10 through 12 to mount the rafter assemblies to the top plates.

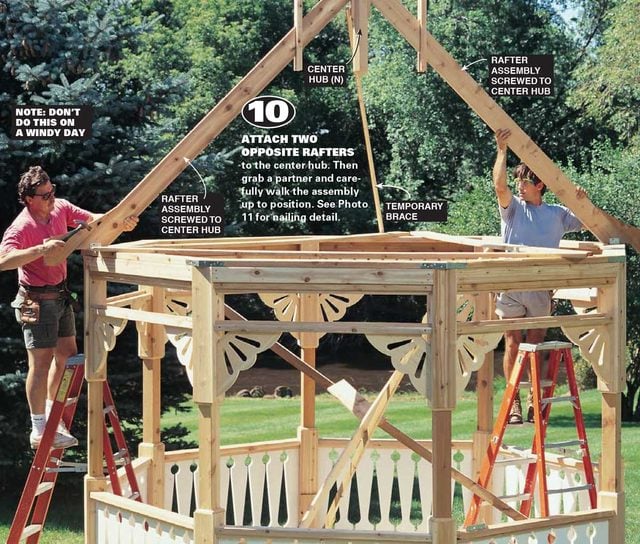

Attach Two Opposite Rafters:

- Attach two opposite rafters to the center hub.

- Then grab a partner and carefully walk the assembly up to position.

Nail the Angled Plates

- Nail the angled plates to the rafter and to the top plates to secure the rafters to the structure.

Fasten Each Rafter System

- Fasten each rafter system to the center octagonal hub.

- Install opposite sides one after the other to maintain the shape of the octagon.

Screw the Horizontal Rafter Ties

- Screw the horizontal rafter ties to the sides of each outer vertical rafter tie.

Nail the Lower Fascia

- Nail the lower fascia (R1) to the rafter tail ends.

- Miter the ends with the saw set at 22-1/2 degrees.

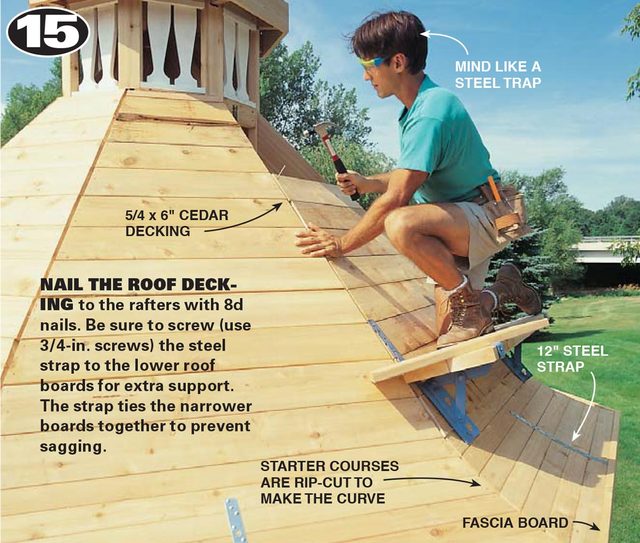

Nail the Roof Decking

- Nail the roof decking to the rafters with 8d nails.

- Be sure to screw (use 3/4-in. screws) the steel strap to the lower roof boards for extra support.

- The strap ties the narrower boards together to prevent sagging.

- Cut your lower fascia from 1×10 cedar. Hold it 7/8-in. above the ends of the rafters so your roof decking will be flush with the fascia.

- Rip 5-1/2-in. decking in half for the first seven courses so they’ll be able to bend around the lower curved section.

- Cut each end of the decking at 22-1/2 degrees for the first course and change the angle slightly until you finally reach about 16 degrees for the rest of the full-width courses.

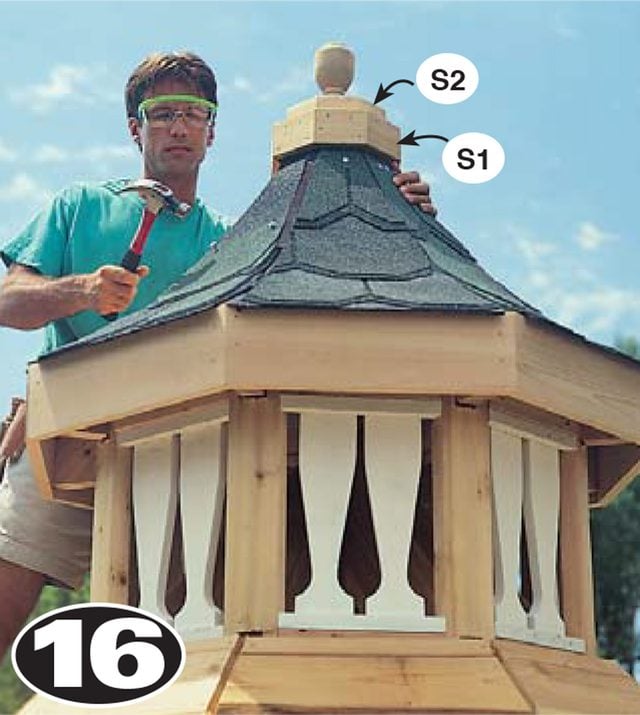

Shingle the Cupola

- Shingle the cupola before shingling the lower roof. Otherwise, you’ll damage the lower shingles when you go up and down.

- There are a few things you need to know about using the Carriage House Shangle roofing material.

- First of all, these shingles are heavy, and a bit tougher to work with than ordinary asphalt shingles.

- They also cost about twice as much, but we thought the finished look was well worth it.

- Don’t buy the special cap shingles for the ridges; full cap shingles will look out of place.

- Instead, buy a matching color of ordinary asphalt shingles. You can cut these to fit the width and proportion of this small structure.

- At the cupola where the surfaces are all curved, you’ll need to remove the top one-third of each shingle to get it to lie flat.

- The cap over the seams should be cut narrower and shorter to follow the concave curve.

- Another thing to remember for the lower section: The cap shingles should be full width, but the length on the bottom four rows of cap needs to be cut down several inches to make the curve.

Shingle Each Lower Roof Section

- Shingle each lower roof section, then move to the opposite side.

- Keep the exposure consistent from side to side by measuring as you go.

Painting Your Gazebo

- Once you’re done building your gazebo, give it some color!

- Prime and paint if you please, but keep in mind that painting the gazebo means a lot of prep and repainting work in the future.

- It’s best to paint just the gingerbread features as accents, and then seal the unpainted parts with a brush-on oil sealer.

- We’d recommend applying the oil first, then painting the next day.

- Don’t bother oiling the underside of the roof. Because it’s out of the weather and direct sun, it’ll look fresh for years to come.